Self Actuated Control Valve ZZYP Serial

InstruthinkZZYP serial self-actuated control valve does not require any external energy sources. It is adjusted by flow medium automatically. It has the advantages of using no electricity and no gas source site.

- Price Term: FOB/CIF/EXW/DAP

- Package: Exported Wooden case or according to customer request

- Delivery Time: 7 to 10 working days

- Transports: By sea, by air, by high express

- Shipment Port: Shanghai Port

- Origin of Place: Jiangsu

- Warranty: 12 Months

InstruthinkZZYP serial self-actuated control valve can be adjusted the pressure setting during operation. The quick opening flow characteristics are sensitive and of good sealing performance. It is widely used in petroleum, chemical, electric power, metallurgy, food, textile, machinery manufacturing, and residential construction buildings, and other industrial equipment for the medium of gas, liquid, and steam. And they have the function of pressure reducing (for valve adjustment) or relief, regulating pressure (before adjustment for the valves), and automatically controlling.

- Features

- Specification

- Actuator

- Performance

- Allowable working temperature

- Structure

- Dimension and Weight

- Actuator and weight

- Order information

- Code

- Diaphragm type with sensitivity adjustment and fast response of the pressure change

- Piston cylinder with high-pressure resistance and large adjustable travel

- Single-seat control valve, sleeve valve types for wide-range control

- For controlling the downstream pressure

| Body Type | Single seated, globe type |

| Size | DN15~DN250 (3/4″ to 10″) |

| Pressure Class | 1.6, 4.0, 6.4 Mpa; |

| ANSI 150, ANSI 300, ANSI 600 | |

| Characteristics | Quick open |

| Body Materials | WCB, CF8M, CF3M, CF3 |

| Trim materials | Stainless Steel |

| Temp range | – 5°C to ~ +70°C |

| Connection | Flanged, Socket welding, Butt welding |

| Gland packing | PTFE, Braided PTFE, Grafoil |

| Actuator | Pneumatic diaphragm actuator, Piston |

| Accuracy | Within ±5% |

| Diameter DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| Rated Flow Factor KvS | 4 | 6.3 | 8 | 16 | 20 | 32 | 50 | 80 | 125 | 160 | 280 | 320 | 400 | |

| Noise factor Z Value | 0.6 | 0.6 | 0.6 | 0.55 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 | 0.35 | 0.3 | 0.2 | 0.2 | |

| Allowable Differential pressure

(Mpa) |

PN16 | 1.6 | 1.5 | 1.2 | 1.0 | |||||||||

| PN40 | 4.0 | |||||||||||||

| Active Area(cm)2 | 32※ | 80 | 250 | 630 |

| Setted pressure range (MPa) | 0.8~1.6

0.3~1.2 |

0.1~0.6

0.05~0.3 |

0.015~0.15

0.01~0.07 |

0.005~0.035 |

| Min pressure △Pmin(MPa) | ≥0.05 | ≥0.04 | ≥0.01 | ≥0.005 |

| Max differential pressure (MPa) | 2 | 1.25 | 0.4 | 0.15 |

| Material | Diaphragm cover: Galvanized steel; Diaphram: EPDM or FKM fiber | |||

| Control pipeline, adaptor | Copper pipe or steel pipe 10×1; Ferrule type connector: R1/4 “ | |||

Note:※This pressure range is not for DN150 to DN250

| Set allowable error | ±8% | |||

| Allowable leakage

|

Metal seal | 4×0.01% rated capacity | ||

| Soft seal | DN15~50 | DN65~125 | DN150~250 | |

| 10气泡/min | 20气泡/min | 40气泡/min | ||

| Diameter | 15~125mm | 150~250mm | |

| Seal type | Metal seal | ≤150℃ | ≤140℃ |

| Cooling tank ≤200℃ | Cooling tank& length pipe ≤200℃ | ||

| Cooling tank & fin ≤350℃ | Cooling tank& length pipe≤300℃ ※ | ||

| Soft Seal | ≤150℃ | ||

Note: ※ the allowable working temperature for valve, only when the medium is a valve, if the working temperature reaches 350 °C, please select PN 40 valve body.

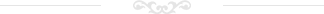

| 1 | Body | 2 | Seat | 3 | Shaft | 4 | Bonnet | 5 | Diaphragm cover | 6 | Diaphragm |

| 7 | Spring | 8 | Adjusting nut | 9 | Guided pipe | 10 | Bellow | 11 | Balance diaphragm | 12 | Charging valve |

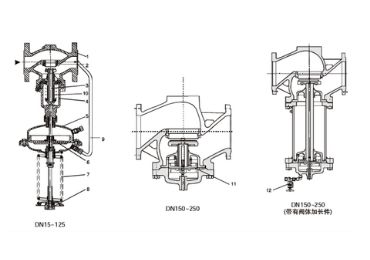

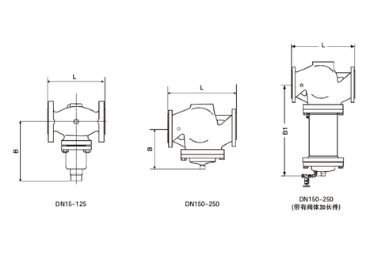

| DN (mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

| L (mm) | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 |

| B (mm) | 212 | 212 | 238 | 238 | 240 | 240 | 275 | 275 | 380 | 380 | 326 | 354 | 404 |

| Weight (Kg) | 6.2 | 6.7 | 9.7 | 13 | 14 | 17 | 29 | 33 | 60 | 70 | 80 | 140 | 220 |

| B1 (mm) | – | – | – | – | – | – | – | – | – | – | 630 | 855 | 1205 |

| Weight (Kg) | – | – | – | – | – | – | – | – | – | – | 140 | 210 | 300 |

| Active Area(cm)2 | 32 | 80 | 250 | 630 |

| R (mm) | 172 | 172 | 263 | 380 |

| H (mm) | 435 | 430 | 470 | 520 |

| Weight (Kg) | 7.5 | 7.5 | 13 | 28 |

- Model and Name

- DN(mm) Diameter

- Working pressure

- Flow Characteristic

- Body material

- Rate Flow rate Factor

- Medium and working temperature

- Inlet and outlet pressure (differential pressure )

- Control signal

- another special requirement

| ZZYP | Structure type | Nominal pressure | Body material | Mode of action | Condensator | Pressure control scope (KPa) | Nominal diameter |

| Self-operation control valve | P: Single seat

M:Sleeve type |

PN16=16

CL150LB=150 LB |

C=WCB

LC=LCB P=CF8 PL=CF3 R=CF8M RL=CF3M D=Special material |

B:

Backstream pressure control K: Upstream pressure control |

No: without

C: with condensator |

15~50 40~80

60~140 120~220 160~220 200~260 240~300 280~350 330~400 380~450 480~560 540~620 600~700 680~800 780~900 880~1000 950~1500 1000~2500 |

DN50= DN50

NPS2〞=NPS2〞 |

| For example Single self-operated control valve, Nominal pressure PN16, WCB material, without condensation, pressure scope: 120—220KPa. Size DN50, Model : ZZYP-16C-B-120~220-DN50 | |||||||

Installation, use, and maintenance

1. Installation

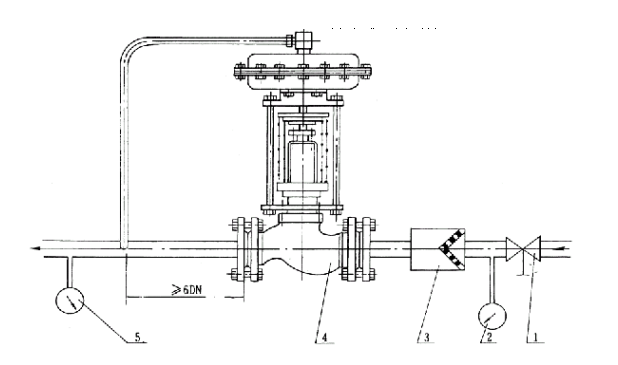

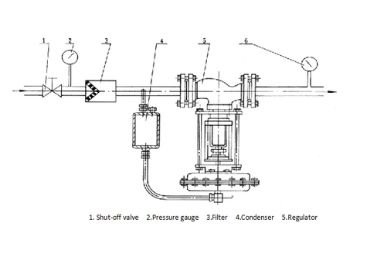

When the valve is used at room temperature (≤ 80°C) in gas or low viscosity liquid media, it is the same as the usual pneumatic film control valve installed upright on a horizontal pipe, as shown in the figure below.

A.ZZYP-16B Type Self-operated pressure regulating valve

- Globe valve 2. Pressure Gauge 3. Filter 4. Self-operated pressure regulating valves 5. Pressure Gauge

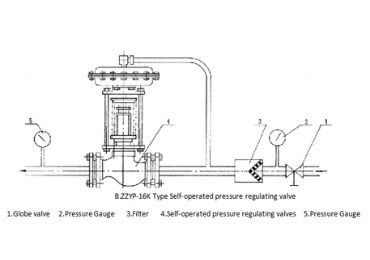

If the medium used is steam, the self-operated pressure regulating valve should be installed upside down on a horizontal pipe, as shown below.

When installing, pay attention to the following points:

- The condenser must be above the actuator of the regulator and below the post-valve (post-valve regulator) or pre-valve (pre-valve regulator) receiver to ensure that the condenser is filled with condensate.

- The pressure point should be taken at a suitable location from the regulator, the pre-valve regulator should be greater than two times the diameter of the pipe, and the post-valve regulator should be more significant than six times the diameter of the tube.

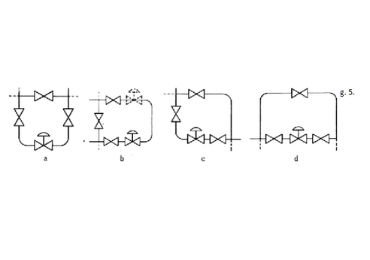

- on-site maintenance and operation, the regulator should be surrounded by appropriate space, and a

Note: The dotted line in the diagram indicates the alternative permissible orientation of the pipe entrances and exits

4. If the diameter of the regulator is too large (DN ≥ 100), there should be a fixed bracket.

5. The direction of media flow is the same as the arrow on the valve body. The center of the pipe before and after should be aligned with the center of the two flanges of the regulator to avoid excessive stress on the valve body.

6. A filter should be installed in front of the valve to prevent blockage by impurities in the medium.

7. Control valves should be installed at ambient temperatures not exceeding -25°C to 55°C.

2. Use

Operating procedures when using gases or low viscosity liquids at room temperature:

- Slow opening of the shut-off valve before and after the valve.

- Loosen the vent plug until the gas or liquid escapes from the actuator.

- Then retighten the vent plug, and the regulator is ready for operation. The required pressure value can be obtained by adjusting the pressure regulating disc. When revising, pay attention to the pressure indication and move slowly so that the valve stem does not follow the rotation.

Operating procedures when using steam:

- Unscrew the liquid filling port screw from the condenser.

- Unscrew the actuator exhaust plug.

- Use the leaky tip to add water through the fill port until it flows out of the vapor discharge hole.

- Tighten the venting plug and continue filling until it overflows the fill port.

- Tighten the liquid filler screw.

- Slowly open the shut-off valves before and after the regulator.

- Adjust the pressure adjustment dial and observe the pressure indication until the required value is reached.

Maintenance

After the control valve is put into operation, the general maintenance workload is minimal, usually as long as the observation of the valve before, after the valve pressure value is in line with the process. The required value can be observed. In addition, keep whether the stuffing box and the actuator are leaking, and if they are leaking, tighten or replace the packing and diaphragm.