Instruthink Vortex flowmeter is the advantage and hot sales products in our factory. It has SIL2, CE, Explosion-proof certificates. With 20 years of vortex flowmeter manufacturing experience, Instruthinkhas strong technical background and support for vortex flowmeters.

- Internal consumption circuit and anti-vibration sensor

- Low power consumption LCD display

- Integrated temperature and pressure compensation

- Instruthinkvortex flowmeter can resist high temperature

- Easy installation, convenient maintenance, and reliable operation

Your Best Vortex Flowmeter Manufacturer from UK

As an ISO registered company, Instruthinkhas more than 20 years of experience in manufacturing vortex flowmeters.

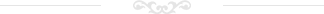

Instruthinkvortex flowmeter is widely used in different industries like steam measurement, compressed air measurement, textile industry, paper industry, heat supply industry, water supply system, metallurgical industry, plastics processing industry, etc.

Instruthinkhas two automatic vortex flowmeter calibration systems. Our vortex flowmeter accuracy is 1.5%, there is a tracking calibration report.

One vortex flowmeter is calibrated twice before delivery. There is a strict quality control system in InstruthinkFactory.

Furthermore, the Instruthinkvortex flowmeter has got a good quality reputation and has got certificates of CE, SIL2, Rohs, etc.

Welcome to send us an inquiry about vortex flowmeter.

One-step Vortex Flowmeter Solution

Flange Connection Vortex Flowmeter can be used in the pipe sizes between DN15 and DN300.

High Pressure Vortex Flowmeter max pressure can be 4-5Mpa depending on the medium and temperature.

Remote Type Vortex Flowmeter can realize remote display at 5 meters away from the flowmeter.

InstruthinkGas Wafer Vortex Flowmeter features simple structure, there is no holes and gaps design, so no , no moving parts inside .

You can use it for measuring food grade liquid, realizing easy installation and convenient maintenance.

You can use an insertion-type vortex flowmeter to measure the big-size pipeline without cutting flow.

Natural gas vortex flowmeter is specially designed for natural gas, air measurement. It features low cost, easy installation, high accuracy.

Your Best Vortex Flowmeter Supplier in UK

Instruthinkvortex flowmeter has an intelligent electric board. It features low-pressure loss, high-temperature resistance, strong anti-interference suppression ability.

It can measure volume flow or mass flow of gas or liquid at full pipe state. There are complete manuals and videos in Instruthink.

If you purchase from Instruthink, you don’t need to worry about the installation and maintenance.

Each part is made by ourselves, such as the electric board, body part. So, our production time is fast. There is abundant raw material in stock.

Instruthinkis your best OEM manufacturer for vortex flowmeters.

Hot Sales Vortex Flowmeter

Instruthinkis Your Best Vortex Flowmeter Partner in UK

- Introduction

- Technical Parameter

- Model Selection

- Calibration

- Packing

- Installation

Vortex flowmeter is setting vortex generation body (bluff body) in fluid, regular vortexs will alternately generate from two sides of vortex generation body.

| Standard | Q/320831AHH003-2004 JB/T6807-93,ISO,CE | ||

| Medium | Gas, liquid, steam | ||

| Caliber | Flange holding (clamp-on) type | 25, 32, 50, 80, 100, 150, 200, 250, 300 | |

| Flange connection type | 100, 150, 200, 250, 300 | ||

| Measuring Range | Normal range of flow speed | Reynold number 1.5 * 104 ~ 4 * 106; gas 5~50m/s;

liquid 0.5~7m/s |

|

| Normal range of flow rate | Liquid, gas flow range-sheet2;

steam flow range-sheet 3 |

||

| Accuracy | Class 1.5 | ||

| Temperature | Normal temperature -25℃~100℃

High temperature -25℃~150℃ -25℃~250℃ |

||

| Output Signal | Pulse voltage output signal | Square wave pulse | |

| Current remote signal | 4 ~ 20 mA, transmission distance 100m | ||

| Environmental Conditions | Temperature: -25℃~+55℃ humidity: 5~90% | ||

| Material | SS, Aluminum Alloy | ||

| Power | 24 V DC or lithium battery 3.6V | ||

| Ex | Exd II BT4 | ||

| Protection Class | IP65 | ||

| Requirements to front & back straight tube section | See Diagram 14 | ||

| Code | Nominal Diameter (mm) | Flow Range (m3/h) | Remarks | |||

| JC-080-25

JC-080-32 JC-080-40 JC-080-50 JC-080-65 JC-080-80 JC-080-100 JC-080-125 JC-080-150 JC-080-200 JC-080-250 JC-080-300 |

DN25

DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 DN300 |

1.4~12(L) 8.8~124(G) 7-124(S)

2.0~20(L) 15~200(G) 12-200(S) 3.2~36(L) 23~300(G) 18-300(S) 5~56(L) 35~450(G) 28-450(S) 8.2~96(L) 63~820(G) 50-820(S) 12.5-145(L) 90~1200(G) 75-1200(S) 20~224 142~1950 120-1950 30~352 220~3000 175-3000 44~512 320~4400 260-4400 79~920 565~7800 440-7800 140-1200 850-12400 720-12400 175-2020 1250-17500 1020-17500 |

1. Make reference to sheet 3 for a steam flow range

2. DN250 ~ DN600 can be provided according to customers’ requirements 3. For DN300 and above, we recommend Insertion Type Vortex Flowmeter 4. L is liquid, G is gas, S is steam |

|||

| Code | Function 1 | |||||

| N

Y |

No Temperature & Pressure compensation

Temperature & Pressure compensation provided |

|||||

| Code | Output Code Output | |||||

| F1

F3 F5 |

4 ~ 20 mA (two wires) F2 4-20ma (three wires)

RS 485 interface F4 Pulse/Frequency Hart |

|||||

| Code | Medium Code Medium | |||||

| J1

J2 |

Liquid J3 Steam

Gas |

|||||

| Code | Connection | |||||

| L1

L2 |

Wafer Type

Flange Connection Type |

|||||

| Code | Function 2 | |||||

| E1

E2 T1 T2 T3 P1 P2 P3 P0 D1 D2 I R |

1.0

1.5 Normal temperature High Temperature Steam 1.6 MPa 2.5 MPa 4.0 MPa Special pressure Internal 3.6 V 24V DC Integral type Remote type (10M cable ) |

|||||

Vortex Flow Meter – FAQ(Frequently Asked Questions)

What is a Vortex Flow Meter?

The vortex flowmeter is a flow measuring device. It is most suitable for measuring the problems caused due to moving parts. You can buy vortex flowmeters, available in industrial-grade brass construction.

If you compare the vortex flowmeter with other types of flow meters, it is less sensitive to changes in process conditions. This is because it has no moving parts. As a result, you will face relatively low wear in your equipment.

What are the phases of the process fluids measured using a vortex flowmeter?

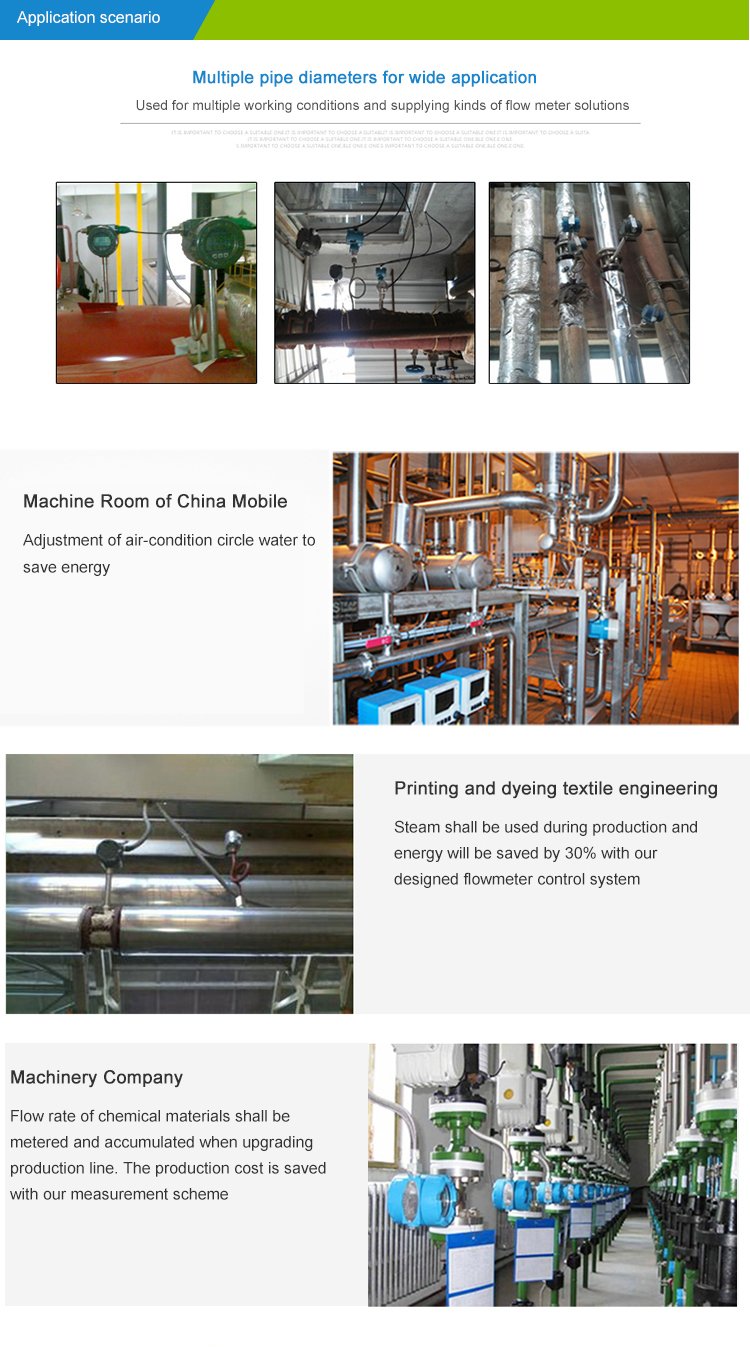

You can measure the flow rate of different phases of process fluids. For example, vortex flowmeters are widely used in various industry fields, measuring the volumetric flow of liquids, gases, and steam.

What does a vortex flowmeter measure?

You can measure the fluid velocity by using a vortex flowmeter which indicates the flow rate of the process. The vortex flowmeter uses a working principle called the von Kármán effect to measure fluid velocity. When the flow passes through a bluff body, a repetitive vortex pattern is produced.

What is the vortex flowmeter working principle used?

The vortex flowmeter is an instrument used to measure liquid flow.

The working principle of the vortex flowmeter is vortex shedding. An oscillating vortex will be generated when fluid such as water flows through the bluff body (relative to the streamlined type). The frequency of vortex shedding depends on the size and shape of the object.

The vortex flowmeter uses a working principle called the von Kármán effect to measure fluid velocity. When the flow passes through a bluff body, a repetitive vortex pattern is produced.

What is the cause of water hammers in vortex flowmeters?

You may have seen the water hammering in the flow. It refers to the banging effect of the water pipe after turning on the shower. You will observe that it is caused by the valve opening or closing too fast. The flow of water through the pipe is fast enough to produce a punch.

You will face financial loss due to the water hammer. The danger is that commercial pipelines produce water hammers too quickly, which may damage your sensors. Therefore a vortex flow meter is usually used in such conditions to measure the flow rate of process fluids.

How can you prevent water hammers with vortex flowmeters?

Yes, you can solve this problem by using the vortex flowmeter. To avoid this problem in a steam system, you can reduce the pressure by slowly opening and closing the valve to reduce condensation.

When you face a water condensation problem in the system, water hammering starts. Vortex flowmeters help you to measure the flow rate of steam in such conditions in an effective way.

What is a vortex breaker?

When you discharge the process fluid from any sort of tank, a vortex forms, you can solve this problem using the vortex separator. The vortex separator is a device designed to prevent vortex formation when fluid (liquid or gas) is discharged from a container (such as a storage tank or a vapor-liquid separator).

The vortex formation will entrain steam in the liquid stream, resulting in poor separation of process steps such as distillation or excessive pressure drop or cause cavitation in downstream pumps.

Why is the vortex flowmeter not suitable for slurry or sludge flow applications?

You cannot measure the flow rate of sludge and slurry using a vortex flowmeter.

Vortex-shedding flowmeters are not suitable for such applications. In addition, when you measure multi-phase flow (solid particles in gas or liquid; gas bubbles in liquid; liquid droplets in gas), vortex meter accuracy will decrease because of the meter’s inability to differentiate between the phases.

Slurry fluids contain different types of impurities/particles along with. Therefore, vortex flowmeters do not give accurate results for such fluids, and usually, it is not recommended.

How does a vortex flowmeter work?

You can control the speed of the working fluid is proportional to the frequency of the vortex generated by the discharge rod. Use known cross-sections—the area of the pipe.

What caused the vortex?

To understand the causes of the vortex, you consider that vortex is a physical phenomenon that occurs when gas or liquid moves in a circle. In the center is a vortex line, and matter revolves around it.

They are formed when the velocities of objects surrounding a straight line are different. Hurricanes, tornadoes, and the air above the wings of an airplane are all examples of vortices.

Do vortex flowmeters survive in hazardous places?

Yes, you can also install the vortex flow maters in hazard-associated areas. These meters are not affected by harsh conditions.

Why Vortex Flow Meters are the Champions of Steam Applications?

You can say the vortex flowmeter is the champion of steam flow rate measurements. The Steam application is good for various tasks in many industries. Affordable, efficient, and harmless steam is a powerful source of heat energy. Moreover, its adaptability makes it a key component wherever heat distribution is required.

However, you can use it whenever a process involves steam; additional attention and attention are required. Higher temperatures and pressures make safety a real issue for you, and the water droplets produced by condensation can cause excessive wear on the equipment of your process industry.

You have the option of vortex flowmeters. It is particularly suitable for measuring the flow of superheated and saturated steam. Their innovative in-situ design improves the safety and efficiency of operations. Combining complex eddy current technology with pressure and temperature sensors provides the ultimate.

Can we use vortex flowmeters for non-conducting process fluids?

Yes, you can use these vortex flow meters for non-conducting process fluids like mineral oil. Vortex flowmeters have a wide range of applications in the process industry.

Are vortex flowmeters recommended for high-temperature flow rate measurements?

Yes, you can use this flowmeter for high-temperature process fluids. They show high resistance to vibration and thermal shocks.

What are the advantages of Vortex Flow Meter?

Advantages

- You can Measures Gas, Liquids, and Steam.

- You can able to obtain high accuracy and repeatable measurement

- There are high Temperatures that can be accommodated

- You can maintain low sensitivity to variations in process conditions

- Resistant to vibration and thermal shock

- You can also use for non-conductive fluids

- Multivariate (P, T, and Q) models measure mass flow and heat energy

- Low pressure drops across meter body (Especially in modern ultrasonic bluff bar designs)

- You can install vortex meters vertically, horizontally, or at any angle, as long as they are kept flooded

- The vortex flowmeter is suitable for hazardous areas

- You can obtain the low cost of ownership / proven design

- You require no moving parts, minimizing the risk of clogging

- Re-calibration can be done at extended intervals

Do Vortex flowmeters require frequent calibration?

No, you need not worry about the calibration of the vortex flowmeter. You can calibrate these flow meters for a long time period. There is no need to calibrate the vortex flowmeter frequently. You can schedule its calibration once a year or can extend the time period.

What are the Disadvantages of Vortex Flow Meter?

Disadvantages

- Not suitable for precision batch applications that encounter low “drip” flows

- In some applications, bluff bodies may be coated, affecting the accuracy

- Flow regulation needs to reduce the turbulent flow pattern before the flowmeter

- Unidirectional measurement only

- Not suitable when cavitation occurs

- Not suitable for flow measurement of some phase change liquids or viscous liquids

What is the turn-down ratio of the vortex flowmeter?

You can have the turn-down ratio of the vortex flowmeter of 12:1 at a viscosity of 1 CST. Higher viscosity will reduce the refractive index. You must reduce turbulence in your pipeline because turbulence in the pipeline will affect the accuracy of most flow meters. The source of turbulence is a change in direction in a pump, valve, or pipe.

How do you calibrate a vortex flowmeter?

You can calibrate the vortex flowmeter as;

As you know, the vortex transmitter works according to the frequency of apex shedding. In the calibration, the input pulse signal and the output peak flow frequency are compared with the corrector. The calibrator here is the main calibrator. To perform vortex flow calibration, follow the steps below.

Calculate the vortex shedding frequency:

Vortex shedding frequency = reference coefficient x conversion coefficient x (upper range value unit is gallon/time)

The vortex shedding frequency is expressed in pulses per second (PPS), and the values of RF, CF, and URV are mentioned in the equipment manual.

After you calculate the frequency of eddy current shedding, set the jump point to 5 checkpoints. Then you connect a frequency generator to the input of the transmitter. Finally, connect the output of the calibrator in series with the transmitter.

In addition to this, you set the fine span and adjust it in the following steps.

- First of all, you set the frequency generator to the upper range value and adjust the fine range screw to 100%.

- Then you adjust the output value to zero.

- After that, you disconnect the frequency generator and connect the signal leads. Then adjust zero to a lower range value.

- You have to adjust the zero point until the input and output match.

- You have to perform this process for each of the 5 checkpoints to complete the calibration.

The manufacturer’s guidelines must perform the calibration process.

It is essential to calibrate the flowmeter by an expert.

How can you determine the lower limit of vortex flowmeter in gas, steam, and liquid applications?

You can measure the lower limit of vortex flowmeter in ordinary gas as:

Qρ = q0×√(ρ 0 /ρ)

Qρ: The lower limit of measurement under the density of the medium

Q0: Lower limit

ρ 0: Density reference air ρ 0=1.205 kg/m3

ρ: the density of the measured medium

Note: For lower density and high viscosity such as H2, the measurement limit of the vortex meter will be higher, and the vortex flowmeter may not be suitable for this situation. Only when the work pressure is high.

In the case of liquids, you can use this method:

As you know, there are no moving parts, the vortex flowmeter has a very low-pressure drop, and the flow rate range is 0.3~7m/s, which is an ideal model for liquid applications. However, for other high-viscosity liquids, the viscosity needs to be confirmed.

DN15≤4 marine protection area; DN25≤5 marine protection area; DN40 ~ DN300≤7 marine protection area;

Unit transfer: 1 cp=1mPa·s; 100 cp = 1 p;

1 cst=1mPa·s /g/cm3; 1 CST = 1 square millimeter/sec

You can find the lower limit of vortex flowmeter in steam by using the below-mentioned method:

Usually, you use T/h or kg/has the mass unit of steam. Due to the difference in temperature and pressure, the measurement ranges of saturated steam and superheated steam will also be different.

Q=1.5Q0×=√(ρ 0/ρ )×ρ ×10-3(t/h)

ρ, the density of the measuring medium

Q: Flow rate of the measured medium

ρ 0, Q0: Reference air density (1.205kg/m3) and flow

Note: If you are using the vortex flowmeter for superheated steam, the temperature, pressure, and density need to be confirmed simultaneously.

What is the installation procedure of the vortex flowmeter?

You should meet the Flowmeter installation requirements as;

Before you install the vortex flowmeter, confirm that the installation site allows these considerations.

- You must ensure that the pipeline pressure and temperature will not exceed the rating of the vortex flowmeter.

- You must have the minimum number of pipe diameters that the position meets the requirements.

- Safe and convenient, with sufficient head clearance for maintenance purposes.

- Check whether the cable entering the instrument meets the requirements of hazardous area standards for the cable entry process.

- The equipment you use should be a certified flameproof type suitable for using and installing correctly. You must use at least the degree of protection IP66 to EN60529 can only be achieved when using a certified cable entry suitable for the application and installed correctly. It would help if you closed the unused holes with a suitable punching element.

- For remote installation, you must verify that the provided cable length is sufficient to connect the flowmeter sensor to the remote electronic device.

In addition to this, you must check whether your flow system is abnormal before installation, such as:

Leakage in the lines,

Valves or restrictions in the flow path may cause interference in the flow profile that might cause unexpected flow rate indications.

How is the accuracy of the Vortex Flow Meter affected?

You will face an accuracy problem in the vortex meter when the fluid is not clean. Due to slurry or impurities in the flow, the vortex flowmeter accuracy decreases.

What are the typical applications of Vortex Flow Meter?

Typical applications

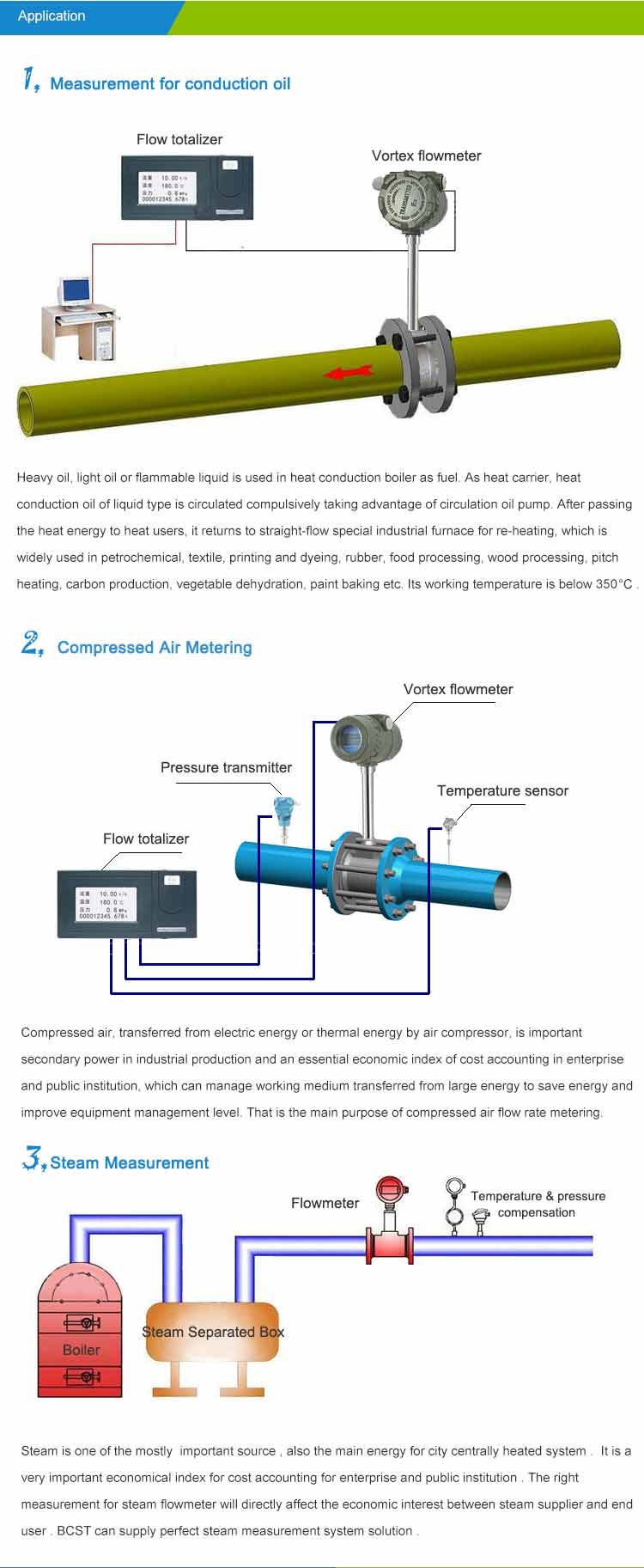

- Steam measurement in the boiler room of thermal power plant

- Marine Fuel measurement at elevated temperatures

- Bio-gas measurement in waste digester operation

- Air measurement of sewage treatment bed-microbial oxidation

What Is K-factor in a vortex flowmeter?

K- factor is an abbreviation of the calibration factor of Vortex flow meters.

The basis of the vortex flowmeter is the von Karman vortex street principle. According to the von Karman vortex street principle, as long as it is designed properly, the Strouhal number is constant in the wide range of Reynold’s number, as shown in the following formula.

F = St * V/D

F = vortex frequency

St = strouhal number

V—velocity

D = diameter of ejector rod

This directly shows that the speed is proportional to the frequency, which is the measurement principle of the vortex flowmeter.

The above are the basic requirements for understanding the k factor, and now your question has an answer.

The k factor is established in the laboratory. It is the pulse generated per unit volume flow (i.e., k =… pulse/m3) divided by f (pulse/sec)

Get volume flow (m3/sec)

What sensor is used in a vortex flowmeter?

Piezoelectric sensors are among the most widely used sensors in vortex flowmeters due to their lower initial cost. As a result, many researchers have applied piezoelectric sensors to this. However, under turbulent conditions, the position and performance of the vortex flowmeter of the sensor are rarely reported.