- It can calculate the compensated spate.

- It can replace three single variable transmitters.

- High dependableness.

- Minor installation cost.

- Low preservation.

- Reduce Installation Time

InstruthinkYour One- Stop Multivariable Transmitter Supplier in UK

With over 20 long whiles of experience in manufacturing and 12 whiles of domestics experience, Instruthinkis ready to offer excellent products and services to our customers home and abroad.

Instruthinkis a registered transnational brand in over 100 countries. We’ve ISO 90012000, ISO 14001, ISO 28001, ATEX, CE, RoHS, and SIL2. High-tech installations, professional specialized platoon, good products, and competitive price is what we offer to the globe.

Welcome to visit our workshop

Intelligent Multivariable Transmitter Solution Experts from UK

Best Multivariable Transmitter Solution for Your Project

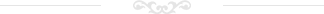

Instruthinkmultivariable transmitter measures and calculates the mass affluence as a function of a discriminational pressure as well as absolute pressure and the temperature. Instruthinkmultivariable transmitter is suitable to measure liquid, gas, or smoke affluence and discriminational pressure.

Instruthinkoffers JCMT multivariable transmitter with temperature detector, JCMT multivariable transmitter with Hart, JCMT multivariable transmitter with RS485, and JCMC multivariable transmitter.

Welcome to communicate us for your inquiry.

Hot Sales Multivariable Transmitter

Your Best Multivariable Transmitter Manufacturer from UK

- Certificate

- Introduction JCMT

- Production

- Installation

- Multivariable Transmitter Calibration

Introduction-multi-variable -transmitter

Introduction-multi-variable -transmitter

Multivariable transmitter-FAQ

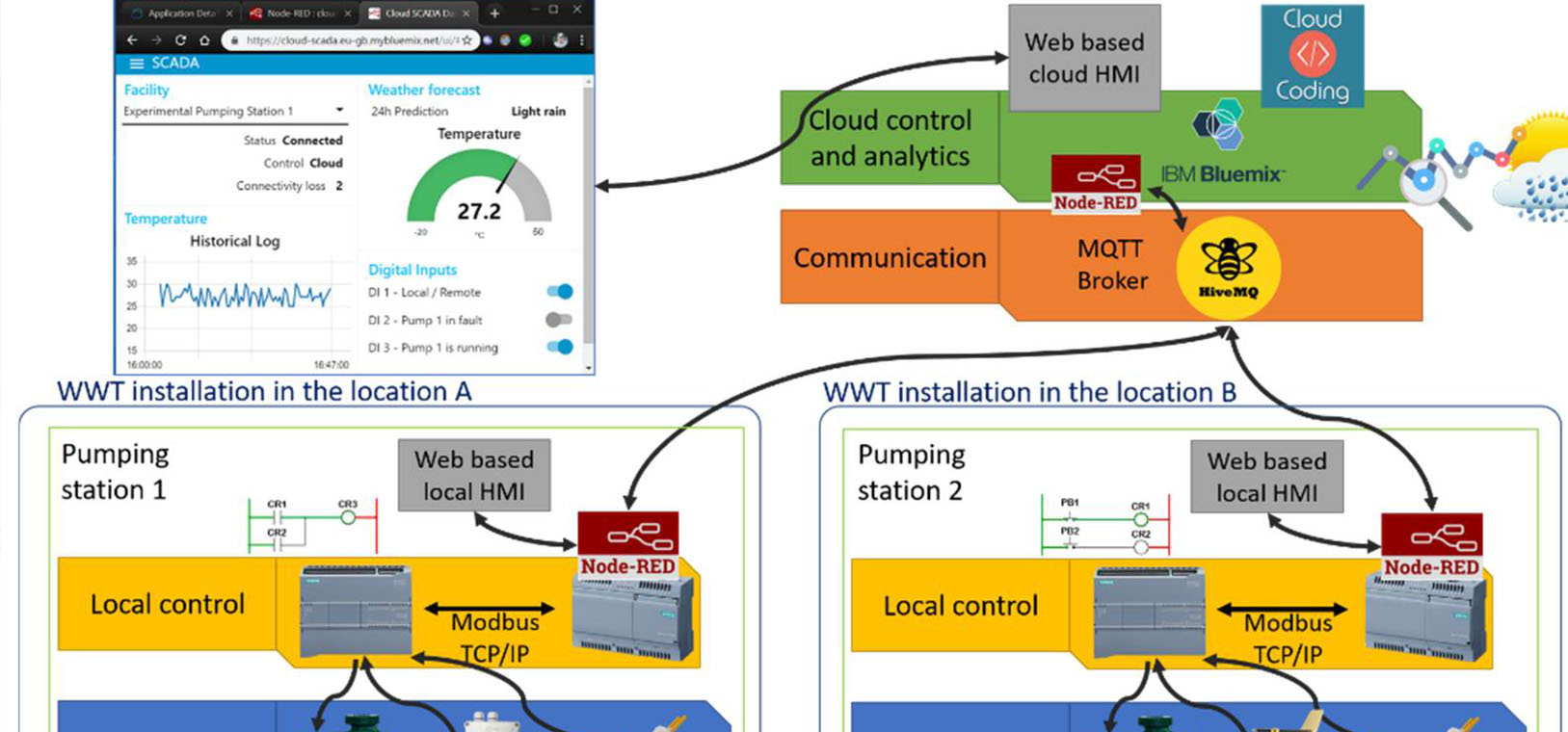

For more than 20 years, Instruthinkhas been manufacturing and supplying high quality, including the flowmeter, valves, and transmitters such as a multivariable transmitter. Every multivariable transmitter goes through a testing process with the tracking certifications. As a result, each type of multivariable transmitter is available according to the requirements of the customer and their applications. Instruthinkis also among the best suppliers of multivariable transmitters across the world.

Following are the answers to all the queries about the multivariable transmitter that you are looking for:

1. What is a multivariable transmitter?

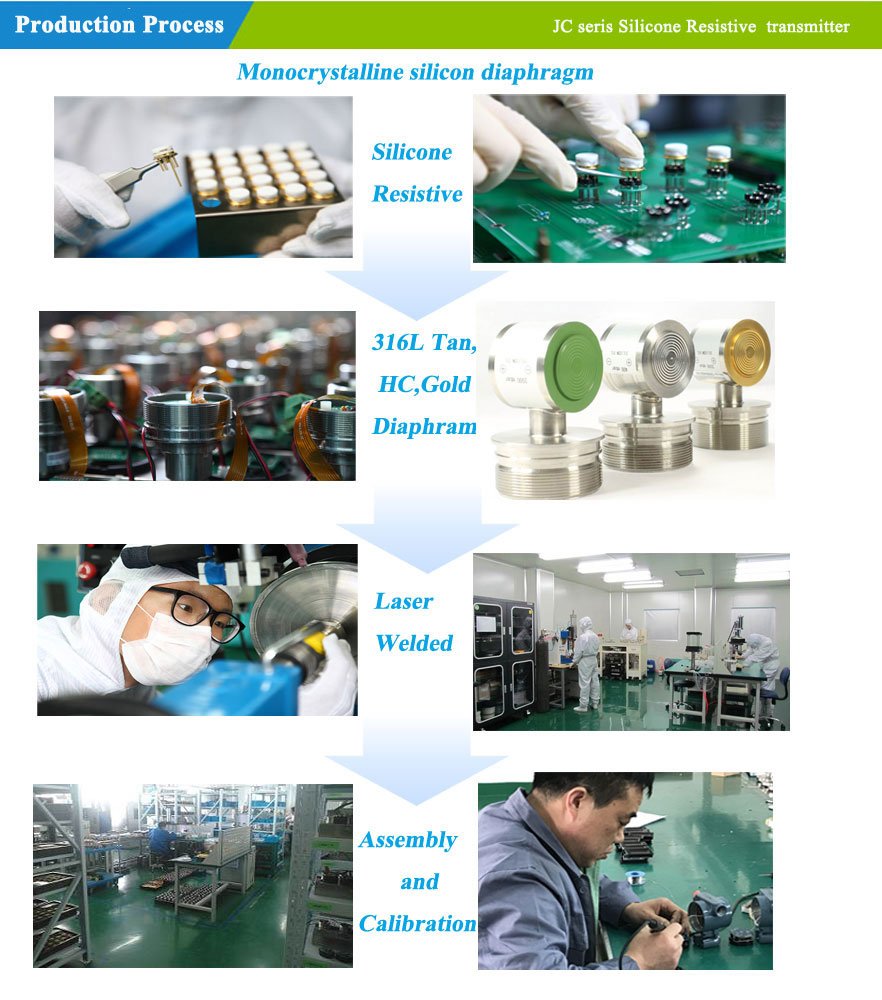

The multivariable transmitter is the differential pressure transmitter that can measure temperature, static pressure, and other values. You can name these values as independent processing variables that are useful in compensating whenever there is a change in the density and viscosity of the medium. The multivariable transmitter also allows you to measure the parameters of the flowing medium whenever you are using it as a flowmeter. While operating as a differential pressure transmitter helps measure temperature, pressure, and differential pressure at similar timings. In real-time, the multivariable transmitter permits you to calculate the compensating flow of the mass. The multivariable transmitter facilitates the more correct readings while comparing with the primary differential pressure transmitters. The rate of accuracy is low in typical differential pressure transmitters. Because it cannot measure the variations of the pressure and temperature. The turndown ratio of the multivariable transmitter is 14: 1, which delivers high accuracy during the more extensive range of the flowing medium.

The applications of the multivariable transmitter are custody transfer, balancing the energy and material. You can also optimize and control through the multivariable transmitter.

2. What are the types of multivariable transmitters?

- JCMT multivariable transmitter with the temperature sensor: JCMT helps measure the differential pressure, flow of steam, or gas. JC1005 outputs 4-20 mA DC /Modbus RS485/pulse signals corresponding to the measuring flow or differential pressure. The accuracy rate is high, and stability in the sensor also measures the static pressure displayed on the integral indicator or monitoring remotely through various communications. Other prominent features are giving responses quickly, setting up the remote by using the contacts, self-diagnosis, and the option of displaying the status of the output for alarming high or low pressure.

- JCMT multivariable transmitter with the RS485: This multivariable transmitter is with the RS485 serial output for the data, isolated, and protocol of ASC II. This multivariable transmitter is accessible by using the instrument setup of the software available on PC. The JCMT multivariable transmitter with RS485 is with the signals and suitable for industries transducer signals analog or pulse.

- JCMC multivariable transmitter with the hart: This multivariable transmitter has a differential pressure sensor module along with the integration of the electronic adaptor unit. It is an amplifier module adjacent to the controlling unit and two-wiring system. The RTD terminal for input helps in measuring the temperature of the process.

What does the multivariable transmitter measure?

- Mass flow measurement: The multivariable transmitter measures the mass flow of gas, steam, liquid and standard volume of the flowing gas.

- High-pressure direct mass measurement: measuring differential pressure helps measure the mass flow of the gas, steam and liquid by compensating dynamically. There is an improvement in the accuracy rate from 1% to 2% because of the availability of the shaft range, the customization of multivariable transmitters is present, and is easy to install on the Pitot tubes.

- Level measurement: In the level measuring applications, the purpose of a multivariable transmitter is to calculate the fluid density dependent on the pressure and temperature. There is an increase in the measuring accuracy even during the usage of the diaphragm seals.

3. What are the performance specifications of a multivariable transmitter?

- According to the calibrating span, reference accuracy includes linearity on the terminal basis, hysteresis, and repeatability. The accuracy is 0.1%/0.01%. if TD>10 (TD=URL /SPAN):0.0075% *TD/ (0.01% *TD)%

- Ambient temperature effects: -40 to-20 degrees Celsius and 65 to 85 degrees Celsius.

- Static pressure effects: (0.05% URL+0.075% Span)10MPa

- Over pressure effects: 1% *Span/10MPa

- Power supply effects: 001%/10V (12V-42V DC)

- Stability: 1% Span/3 years

- Measuring temperature: -50 to 650 degrees Celsius

- Limits of zero adjustments: You can fully increase or suppress the limits of the upper and lower range of the capsule.

- Adjustment of external zero: You can adjust the external zero continuously with 0.01%, increasing the span resolution. Locally, make the range again by using the settings of the range switch.

4. What benefits do multivariable transmitters provide to oil and gas applications?

The multivariable transmitter is the latest platform for upstreaming and midstream the applications of oil and gas. The multivariable transmitter delivers static pressure, differential pressure, and measuring temperature. All the measurements are by one multivariable transmitter.

Following are the benefits that multivariable transmitter is provided to the oil and gas applications:

- Measuring output efficiency and accuracy: The multivariable transmitter can capture the flow rate from the upper limit of the range of the multivariable transmitter for the accountability of the flow. The multivariable transmitter helps to receive the accuracy at a high level and output efficiency depending on the lifespan of the well.

- Supreme measurement of the performance: The multivariable transmitter can provide the best performance regarding the measurement for the measuring application depending on the oil and gas wells. The new technology of the sensor helps in measuring the rate of flow spikes and guarantee to facilitate the correct account of the production of oil and gas. The multivariable transmitter brings stability in the performance, relying on the lifetime of the well. The multivariable transmitter consistently assures the production and minimizes the cost of the services and equipment.

- Reliability and stability in the signals: In the multivariable transmitter, there is reliability and stability in the signals with the help of Modbus, MVS, or BSAP. The outcome is the best accuracy of the data and more effectiveness in managing the changing conditions of the well. Typically, it is an integration in producing an extensive oil and gas network by transmitting the data towards the flow computers and RTUs. Therefore, the design of the multivariable transmitter is to integrate the flow computer input like ROC and proper the present flow computer that receives the input from the Modbus.

5. What are the advantages of using a multivariable transmitter?

Following are the advantages of using a multivariable transmitter during the measurement of the flow:

- The multivariable transmitter can compensate for the flow readings and can change the pressure and temperature present in the system. Therefore, the multivariable transmitter permits the readings accurately.

- The multivariable transmitter calculates the real-time data simultaneously.

- The multivariable transmitter is economical and efficient. The multivariable transmitter is the best substitute for three various devices for measuring.

- In the multivariable transmitter, the accuracy of the flowing medium is high, and the turndown ratio is high.

- The multivariable transmitter can measure mass, volumetric flow, totalizing flow, the flow of the energy, differential pressure, Gage, static pressure, and processing temperature.

- An alternative output of HART 4-20 mA is present in the multivariable transmitter

- The multivariable transmitter helps in measuring the liquid, steam, and gas.

- The multivariable transmitter can measure the compensating flow

- The multivariable transmitter requires less maintenance, and the cost of the installation is low as well.

- There is an improvement in the product yield and increasing efficiency through the multivariable transmitter.

- It can also measure processing temperature from the detectors of the temperature resistance or thermocouple.

- The multivariable transmitter offers long-term stability

- There is an option of selecting the electronic modules in a multivariable transmitter

6. What is the purpose of using a multivariable transmitter?

The multivariable transmitter measures more than one variable in the process just by using a single instrument. The multivariable transmitter can measure the temperature, pressure, and differential pressure. So, the multivariable transmitter serves as measuring the three different variables. The multivariable transmitter is also capable of measuring the mass flow or computation of the flow. An electronic display in the multivariable transmitter is present to show the processing temperature. The multivariable transmitter also displays the mass and volume of the flowing rate. The compensation option is available in some multivariable transmitters to shrink or expand in the pipeline’s working with the various pressure levels. You can also measure the accurate flowing of the gas by using the multivariable transmitter.

7. How does the multivariable transmitter work?

The operation of the multivariable transmitter is through the microprocessor and helps provide a reasonable accuracy rate and reliability. The composition of the multivariable transmitter is by the sensors, so it can measure the absolute and differential pressure. The sensors are present in the capsule, and these capsules are resistant to the piezo. When you apply the processing pressure on the multivariable transmitter and its diaphragm, it moves towards the sensor and microprocessor. Their combinations perform all the calculations. The multivariable transmitter replaces three transmitters, so there is a reduction in the multivariable transmitter’s installation cost.

8. Which factors to consider during the selection of multivariable transmitters?

The main factor for selecting the multivariable transmitter is choosing the primary element. For example, there are two parts in the differential pressure flow measuring applications: one is the primary element, and the other is the secondary element. The primary feature includes flow nozzles, pitot tubes, wedge meters, and Venturi tubes. The secondary elements are the multivariable transmitter or differential pressure transmitter.

According to the different properties of the fluid, the selection of the primary element is according to the applications. One more factor for the consideration of multivariable transmitters is the requirement and compensation of temperature and pressure. The fluid density changes with the corresponding changes in temperature and pressure. The variation in the density affects the measurement accuracy if there is no compensation in the flow rate. The occurrence of this adjustment is whenever the temperature, viscosity, density, or pressure impacts the flow rate.

9. Where do you use the multivariable transmitter?

The multivariable transmitter helps measure the differential pressure of the flow in various applications. For example, you can use a multivariable transmitter to measure the volume of the natural gas flowing during the filling of the underground storage under a high level of static pressure. The measurement has to be accurate. The measuring value is the specification of the standard volume of the flowing natural gas.

The multivariable transmitter is also suitable for measuring the level in the applications. The hydrostatic measurement of the level at which the multivariable transmitter provides an economical solution and easy installation. The multivariable transmitter helps in industrial applications whose working conditions are challenging. The multivariable transmitter is suitable for managing the changes in density and temperature affecting the rate of accuracy. You can also record the processing temperature and pressure along with the differential pressure by the multivariable transmitter. The changes in the density of the measuring medium can be corrected through the multivariable transmitter. As a result, there is a visible improvement in the quality of the measurement by the multivariable transmitter.

The combination of the multivariable transmitter is with the sensor, microprocessor, and dynamically flowing compensation. Therefore, it helps in producing the most accurate measurement and consistency in the measurement of the flow.

10. What are the features of a multivariable transmitter?

- The accuracy rate for differential pressure: 0.04%

- The accuracy rate for static pressure: 0.0375%

- The accuracy rate for temperature: 0.2 degrees Celsius

- The multivariable transmitter can compensate the temperature and static pressure automatically.

- The rangeability of multivariable transmitter is approximate 400:1

- The compensating response time of the flow is up to 2 times per second

- The multivariable transmitter can provide multiple displays locally

- The multivariable transmitter can configure, span, and external zero

- The diagnostics are available onboard comprehensively

- Extra protection of overpressure from the multivariable transmitter

- Characteristics of the modular designing in the multivariable transmitter

- There are multiple options for the output in multivariable transmitter: 4-20mA DC supply (analog), digital enhancement (single or multivariable), or HART version 7.0

- The availability of all the options for the output is present in the multivariable transmitter.

11. What are the troubleshooting issues in the multivariable transmitter and their solutions?

| Nothing is visible on the display | · Confirm and make sure that accurate power supply voltage is applying

· And also confirm the connection of the power supply. |

| Fixing of the output at 0 | · Confirmation of the correct settings of the device.

· Check that there are no clogs present in the connecting pipes. · Verify that the valves like stop valve or manifold valve are in the accurate states. |

| Shifting of the output | · Check that there is no leakage of the fluid from the pipes.

· Make sure that fluid is not flowing in the reverse direction · The corresponding directions of the side of high pressure and low-pressure connections are accurate. · Verify that the multivariable transmitter is not slanting. |

12. How is the design of a multivariable transmitter?

The multivariable transmitter accepts modular designing. It comprises a differential pressure sensor along with the integration of the electronic adaptor unit, a module of an amplifier with the controlling unit. The multivariable transmitter also has a two-wiring system RTD terminal for the input that helps measure the temperature of the process. The module of the sensor has a completely welded structure. Inside this module, there is a twin barreling system whose connection is with the overloaded isolation diaphragm; one absolute pressure sensor and other differential pressure are present inside the multivariable transmitter. The installation of an absolute pressure sensor is on the higher side of the pressure and measuring the pressure in the reference value to compensate for the effect from the static pressure. The differential pressure sensor is made by one capillary tube whose connection is with the negative pole of the sensor module.

Extra differential pressure is applied to the diaphragm of the differential pressure sensor by isolating the diaphragm and liquid in the filler. A small variation of the diaphragm changes the output voltage of the testing system. The voltage signals are directly proportional to the input pressure that keeps digitalizing with the help of an adaptor before transmitting into the amplifier. The amplifier performs the linearity on the signal and compensating for the temperature. The three values DP (differential pressure), P (pressure), and T (temperature) get converted into signals that are directly proportional to the mass flow rate. Depending on the different models of the multivariable transmitter, you can establish the connectivity from the female screw on the elliptical flange on the multivariable transmitter. Or the connection can be between the remote flanges and processing pipelines.

13. What are the considerations to install the multivariable transmitter?

There are three divisions of the considerations for installing the multivariable transmitter:

- General considerations: The measuring performance is dependent on the accurate installation of the multivariable transmitter, impulse piping, and sensor of the processing temperature. Always mount the multivariable transmitter near the process and minimize the piping to receive the best performance. Also, consider the requirement of easy accessibility, the proper field for the calibration, and a suitable environment for the multivariable transmitter. The installation of the multivariable transmitter is for the reduction of vibration, shock, and fluctuations in temperature.

- Mechanical considerations: In the steam applications along the processing temperature is more than the limit of the multivariable transmitter, never blow the impulse piping from the multivariable transmitter. Before proceeding towards measurement, close the flushing lines of the blocking valves and fill the lines again with the water. When the mounting of the multivariable transmitter is on its side, place the coplanar flange for receiving the draining or venting correctly. During the gas services, keep the connections of the venting and draining at the bottom, and during the liquid services, keep on the top.

- Environmental conditions: Accessing the requirements and installation of the cover help optimize the performance of the multivariable transmitter. Mount the multivariable transmitter is beneficial for reducing temperature changes, mechanical shocks, and vibrations. At the external level, avoid the multivariable transmitter to get in contact with the corrosive materials. Note down the limits of the operating temperature.

14. What are the tools for the configuration of the multivariable transmitter?

- Option of integrating the three-button configuration: This configuration is applicable for all electrical and environmental conditions. It can configure the multivariable transmitter and display by the accessibility of the three external buttons except for the flow parameters. The capabilities of zero and span are also present as an option by these buttons without or with selecting the display option.

- Handheld configuration: The multivariable transmitter offers two-way communication and configures between the operator and the multivariable transmitter. The multivariable transmitter configures all the parameters for the safety environments—the designing and testing for fulfilling the requirements by the communication protocols. The multivariable transmitter can work from any handheld configuration device that is with proper validation.

Final thoughts:

The multivariable transmitter measures and calculates the mass flowing as the differential pressure’s functionalities and the absolute temperature and pressure. The main benefit of using a multivariable transmitter is that it measures multiple variables by using this one device. For ordering a multivariable transmitter, visit the official website of the Instruthinkand receive your product within seven working days. Our representatives are available on Skype and WhatsApp to answer all your queries about the multivariable transmitter. So order a high-quality multivariable transmitter now and get it to deliver to your doorstep.