- High Force & Speed of Movement

- High Durability

- High Reliability

- Long Service Life

- Cost-Effective

- High-Quality Pneumatic Actuators

InstruthinkYour Best Pneumatic Actuator Supplier from UK

Instruthinkpneumatic actuators can convert the energy of compressed gas or gas into a mechanical motion that regulates one or more final control elements.

Instruthinkoffers a wide range of Pneumatic Actuators, such as ZHA Pneumatic Actuator, Rotary Fork Type Pneumatic Actuator RT Serial, Double Acting Pneumatic Valve Actuator, etc.

Instruthinkpneumatic actuators meet the design specifications offering a satisfaction factor to meet all our customers’ expectations.

Please send an inquiry to understand more about our products.

Instruthinkyour One-Step Solution for Pneumatic Actuator

20 years Manufacturing for Pneumatic Actuator

With Instruthink20 year production history and 12 years of export experience, Instruthinkis your best supplier of Pneumatic Actuator.

Instruthinkhas enough raw materials and a strong technical team that can quickly realize your customized requirements.

Welcome to visit our factory.

Hot Sales Pneumatic Actuator

Pneumatic Actuator-FAQ

A pneumatic actuator is a device that converts and regulates energy into mechanical motion. It is an effective tool for automation control, and you don’t need to depend on human interaction to control the internal mechanism system.

If you want to know about the pneumatic actuator in detail, this guide will be of great help. We will cover basic and most important information about the specifications, mode of operation, and other aspects of a pneumatic actuator.

1. What is a pneumatic actuator?

A pneumatic actuator is a tool that changes the energy of compressed air or gas into motion. This motion can be linear or rotary, depending on the design and model of a pneumatic actuator. The pneumatic actuator uses external force and moves a piston inside the hollow cylinder that builds pressure. This pressure creates a linear force multiplied by the surface area.

A pneumatic actuator is an effective tool that has been part of major industries for decades. There have been advancements or improvements in the design and sealing capabilities resulting in functionality and efficiency.

2. How does a pneumatic actuator work?

The pneumatic actuator is a highly reliable and effective tool in various engineering devices. Its functionality plays a vital role in hundreds of industries. The basic design of the pneumatic actuator consists of a piston, cylinder, valves, or ports. A pneumatic actuator is suitable in applications where pressure is build up.

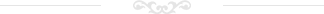

Once the pressure build-up exceeds the required pressure limit, it creates kinetic movement of a gear which can be straight or circular mechanical motion. The diaphragm or piston develops the motion. The air is kept in the upper portion of the cylinder, resulting in pressure to force the diaphragm to move the valve stem.

3. What is the principle of operation of a pneumatic actuator?

The pneumatic actuator uses air pressure to apply force on the diaphragm. This force leads to the movement of the valve actuator and positioning of the valve stem. When the air pressure is applied to the bottom side of the diaphragm of the pneumatic actuator, it lifts the stem of the valve in an upward direction. The amount of force (F) against the surface is equal to the fluid pressure (P) in units of PSI multiplied by the surface area (A), F =PA.

In a circular diaphragm, when the area is equal to πr², the complete formula is F=PAπ². The air pressure for the pneumatic actuator comes from the output of the pneumatic controller that converts an electrical signal into an air pressure signal.

Some of the pneumatic actuators have handwheels to manually position the valve in case of any air pressure failure. There are three manual blocks; two of these blocks flow through the control valve, and the other bypass flow through the control valve.

4. What is the role of the piston in the pneumatic actuator?

The air pressure tubing between the pneumatic actuator and air supply bent into the loop called the vibration loop. This loop minimizes the stain on metal tubing due to the vibration. The pneumatic actuator can take the form of the piston in place of the diaphragm.

The large piston actuator generates a more significant force, and the small valve body needs a larger force to actuate. Piston actuators have longer stroke lengths and can operate at higher air pressures. They can generate more force than the diaphragm actuators with the same diameter.

For instance, the diaphragm operating at the pressure of 35 PSI generates forces of 5388 pounds; the piston actuator of the same size at the pressure of 150 PSI can generate a force of 23091 pounds. The greater force results in more work potential for piston actuators as the mechanical work results from force and displacement W=Fx.

5. What is the role of the diaphragm in the pneumatic actuator?

Unlike the piston actuator, the diaphragm actuator has less advantage of friction. The diaphragm actuators have shorter stroke lengths, so they cannot operate at high air pressures. The less friction of the diaphragm actuator gave them an accurate positioning of the valve stem.

This feature gives the diaphragm actuator an advantage over the piston actuator because precise valve positioning is essential in a pneumatic actuator. The actuator needs to generate more force for moving the valve. For generating the superior force, the actuator piston should have a greater area than the plug.

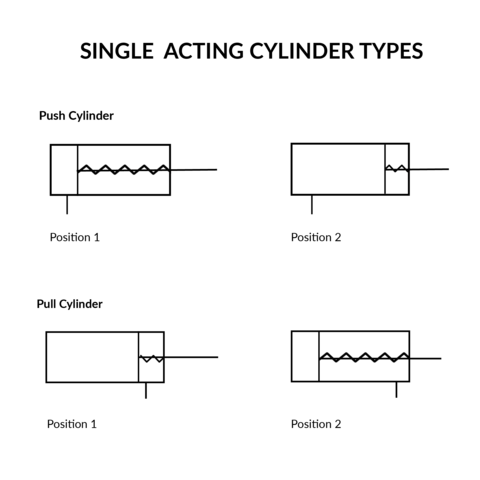

6. What is a double piston pneumatic actuator?

The popular design of the pneumatic actuator consists of a piston and rod inside the closed cylinder. It moves in a straight line to produce linear motion. The double-acting pneumatic actuator develops the thrust in extending and retracting directions. There are ports at each end of the pneumatic actuator, and the piston moves backwards and forward by alternating the port that receives high pressure.

At the end of the pistons, you apply air pressure which produces push stroke and pulls negative stroke. The double-acting actuators are suitable in applications with thrusts and stroke lengths requirements. They are designed based on ISO standards.

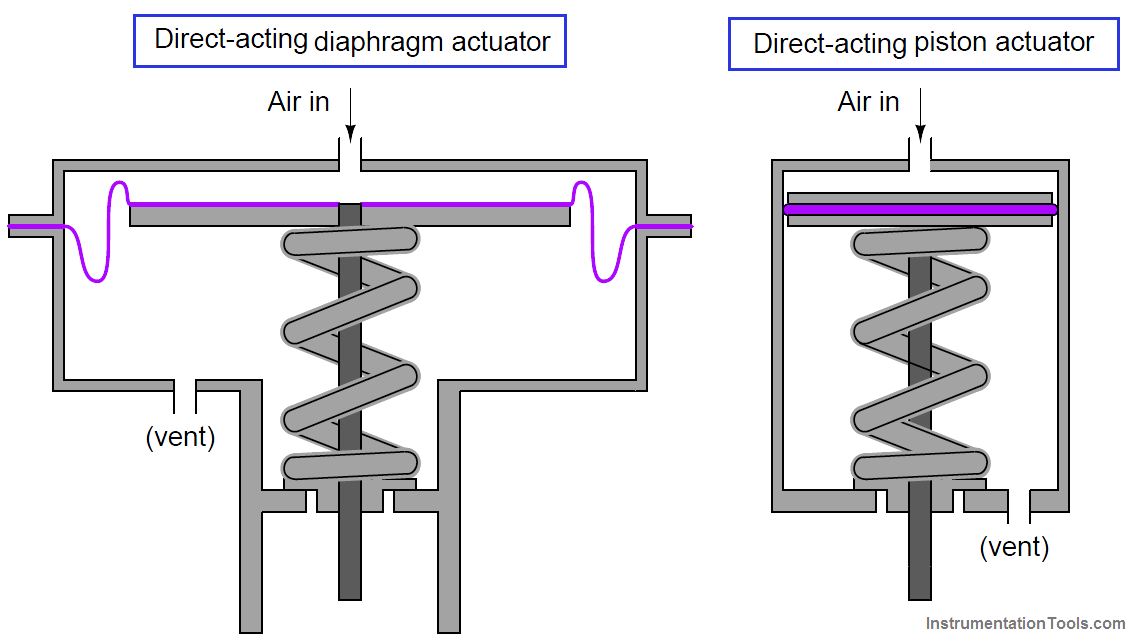

7. What is a single-acting pneumatic actuator?

The single-acting pneumatic actuator consists of a port from where the pressurized air enters in one direction. The port allows compressed air to enter the cylinder and drive it move in the desired direction. The single-acting actuator has two types, push-type and pull-type. In the ‘push’ type, the air pressure produces a thrust by pushing the piston. In the ‘pull’ type, the air pressure pulls the piston by producing a thrust.

The single-acting pneumatic actuator is suitable for applications where work is done in one direction. These have a simple design and compact size.

8. How to select a pneumatic actuator?

The pneumatic actuator is effective for generating accurate linear or rotary motions suitable in harsh environments and temperatures. The selection of the pneumatic actuator depends on the application. Various pneumatic cylinders and actuators are available from 8mm to 320mm that perform different functions for different applications.

Following are some of the factors that you should keep in mind while purchasing the pneumatic actuator:

- You need to select the pneumatic actuatoron whether a linear or rotary movement is required.

- Based on your applications, understand the flow and pressure requirements and then choose the pneumatic actuator.

- Another important factor to consider is the environment. The pneumatic actuators can withstand extreme temperatures are corrosion resistant.

9. What are the key components of the pneumatic actuator?

The key components of the pneumatic actuator consist of a rod, a piston, a scraping seal, a barrel, and sealing gaskets. Compressed air is used to create rotary or linear motion. The pneumatic actuator uses the air to act on a piston inside the cylinder to create movement.

A single-acting pneumatic cylinder has an inlet through which air enters and pushes the piston in one direction. The spring makes the piston to move to its original position. The pneumatic actuator is suitable for slower operations as they use less air and is optimal for lower operating costs. A double-acting cylinder has two holes that allow the pressure of the piston in one direction.

10. What are the applications of the pneumatic actuator?

The pneumatic actuator is suitable for a wide range of applications and is part of various industrial and factory automation systems. The major applications of the pneumatic actuator consist of the production, handling, and packaging of materials. The other common uses of the pneumatic actuator are pistons and ignition chambers in gasoline vehicles.

The pneumatic actuator uses gasoline and ignition of the air to create the force that eventually moves the piston. These actuators are also part of automobile engines, production machinery, and transportation equipment such as railway and aircraft applications.

11. What is the main difference between electric and pneumatic actuators?

The fundamental difference between the electric and pneumatic actuators is the different way of functioning. The pneumatic actuator uses compressed air, while the electric actuator uses electricity to function. Both of them vary in several other ways:

When it comes to cost, the pneumatic actuator has lower initial costs than the electric actuator. Also, they are more cost-efficient. Electric actuators, on the other hand, provide a high level of efficiency and accuracy with low operating costs.

In pneumatic actuators, speed and thrust are linked with one another. With the increase in speed, the thrust also rises. These two components are inversely proportional connected in the electric actuator. The pneumatic actuators are better for industries that need force. Although the electric actuator provides more accurate positioning, various models of both actuators differ in precision.

12. What are the advantages of a pneumatic actuator?

Following are the advantages of the pneumatic actuator:

- The pneumatic actuator has a simple design and provides safety and reliability.

- As they do not depend on the ignition or electricity to convert energy into motion, they are suitable in applications where combustion cannot be tolerated. In these applications, you can store compressed air and use it efficiently with minimum fire risk.

- A pneumatic actuator can be manufactured quickly and are a simple device. It is reliable, durable, and with almost zero maintenance costs. Also, they have long service life if used with care.

- The pneumatic actuator is the preferred device where hygiene is the primary concern. It is because compressed air is free from harmful chemicals, so it protects the application. So this equipment is beneficial in the pharmaceutical, food, and beverage industries.

- It is considered a cost-effective choice in various industries because of its easy installation and maintenance.

- You can install solenoid valves, positioners, limit switches, and manual devices according to your requirements.

- The installation and dimensions of the pneumatic actuator comply with the international standards ISO5211, DIN3337, and NAMUR.

13. What are the drawbacks of a pneumatic actuator?

Despite the number of advantages, the pneumatic actuator has some drawbacks as well.

- The pneumatic actuator’s compressed air and pressure loss make it less efficient than the other linear motion methods.

- A pneumatic actuatoris suitable for a specific job to be efficient. It must have a particular valve size, compressors, and regulators, leading to high cost and complexity.

- The control precision is low in the pneumatic actuator. The actuator cannot return to the pre-set position once the air source is cut when using the double-acting actuator.

14. What is the construction of the pneumatic actuator?

The pneumatic actuator has a manual mechanism for opening and closing the pneumatic ball valve. If it has a hand wheel, you should rotate it anti-clockwise to open it. Otherwise, it will remain closed. There is an internal or external thread at the end of the piston rod, and the sealing of the piston can be repaired and replaced easily.

If the pneumatic actuator has a buffer mechanism, it should adjust the buffer function outside the cylinder. The pneumatic actuator is divided simply into two parts, an actuator and a regulating valve.

15. What are the types of pneumatic actuators?

There are various types of pneumatic actuator, with each type suitable for multiple applications.

Diaphragm type pneumatic actuator

The spring or diaphragm type pneumatic actuator needs compressed air for pushing the diaphragm against a plate. When there is a reduction in pressure, the spring releases the diaphragm. The change in pressure will affect the position of the diaphragm. The diaphragm type pneumatic actuator can ‘fail-open, or fail closed when spring returns to its actual position.

Piston style pneumatic actuator

This pneumatic actuator has a piston inside the cylinder. The piston moves when force is applied at one side of the piston. A double-acting piston-style pneumatic actuator has pressure on both sides, while single-acting has pressure and spring on the other side. These actuators have cylinder diameter and stroke length.

The rotary style pneumatic actuator

This pneumatic actuator has two chambers and works similar to the piston style. It has a paddle that separates the two chambers. When there is a pressure difference, the paddle moves through 90 degrees of travel.

16. What are the designs and models of pneumatic actuator?

Rodless pneumatic actuator

This pneumatic actuator has a structure without any physical rods. They either have a rack and pinion system or gears. Some models of rodless pneumatic actuators depend on magnetically linked cables.

Vacuum generators

Vacuum generators use compressed air and convert potential energy into a usable vacuum. This design is suitable for applications where you need to collect powder and transport it. It is also applicable in situations where you need to remove debris.

Tie-rod cylinders

The tie-rod cylinders have high-strength threaded rods. These are perfect for industrial applications that require beefy equipment. They have small in size, portable, and scalable.

17. What are the specifications of the pneumatic actuator?

Following are the specifications of the pneumatic actuator:

- The valve motion in the pneumatic actuatoris either linear or rotary. Rotary valves include ball, plug, and butterfly valves that rotate at 90 degrees from open to close. Linear motion valves consist of a gate, globe, and diaphragm that push the closure element closed or open.

- The actuator motion is restricted to open or close positions. The actuator allows the throttling of the valve to keep the process in proper proportion.

- The throttling valve regulates the flow, pressure, or temperature in the pneumatic actuator. The valve also adjusts the signal and is called the control valve.

- The input control signal to the pneumatic actuator is a voltage signal.

- The diaphragm actuator is mainly used on linear motion valves, but it is also suitable for rotary motion.

- The pneumatic actuatoris suitable for indoor or outdoor use. The structure protects the harsh environment.

- The actuator has an electromechanical limit switch that allows you to monitor the position of the actuator from a remote location.

18. What are the technical considerations of the pneumatic actuator?

There are some technical specifications and variables that need consideration when configuring the pneumatic actuator. You need to know the sizing data for your actuator, such as valve torque, double-acting or spring return, minimum/maximum operating speed, minimum air pressure, etc.

Solenoid valves pilot the pneumatic actuator. There are five types of the pilot to choose from; double-acting actuator, spring return actuator, remote mount, local mount, and direct mount. The material of the pneumatic actuator is stainless steel, bronze, or aluminum.

Also, you need to specify the pneumatic actuator speed of operation. Positioners are part of the pneumatic actuator to convert the control signal to a valve position.

19. What are the features of a pneumatic actuator?

- The pneumatic actuator is designed in compliance with the latest standards, such as ISO5211, DIN3337, and NAMUR.

- It has a high-intensity aluminum body that has an internal structure with hone anode oxygenation. It makes the equipment long life with swift performance.

- The structure of the pneumatic actuator is compact and modernized. Other multi-specifications make the design economical, cost-effective, and productive.

- It has two independent external stop adjustment bolts that can be adjusted ±5° at open and closed directions.

- The multi-function of the indicator is suitable for mounting accessories.

- Various types of O-rings are available for high and low temperatures

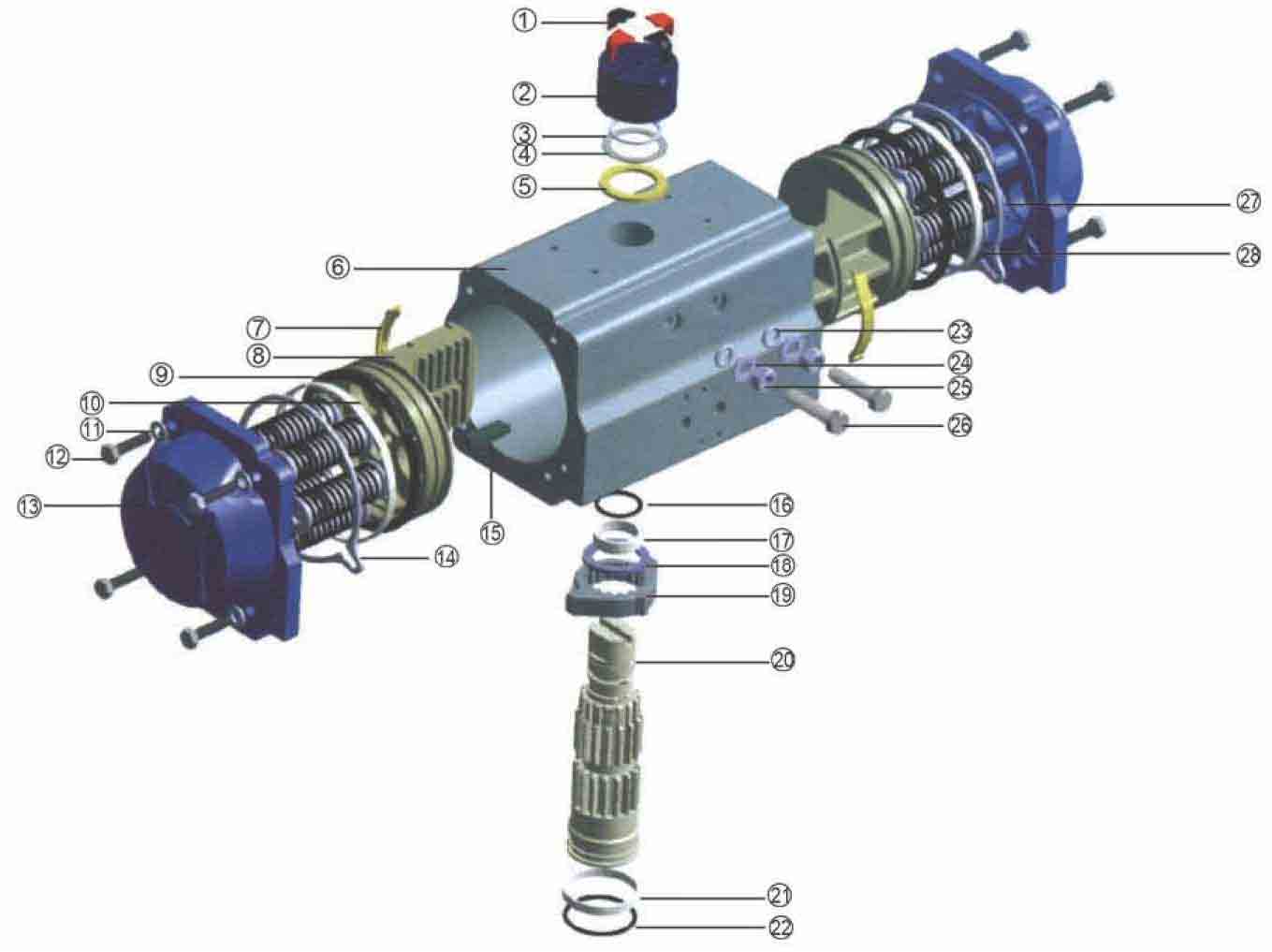

20. What are the components of the pneumatic actuator?

Indicator

The indicator with NAMUR is suitable for mounting accessories in a pneumatic actuator.

Pinion

The pinion is made by nickeled-alloy steel, it is in compliance with the latest standards of ISO5211, DIN3337, and NAMUR. It is nickel-plated to reduce friction and provide maximum wear resistance. You can customize the material in stainless steel and aluminum.

Actuator body

It has an aluminum body anodized to over 30um to make it anti-corrosive and reduce friction to the minimum. The other options of nickel plating and powder polyester are also available.

End caps

They are made of aluminum that provides maximum resistance and corrosion.

Pistons

Pistons have a body of aluminum with hard anodized or cast steel. The unique piston design provides a constant torque on all actuators.

Travel adjustment

The travel adjustment is ±5° in open and closed positions with easily accessible adjustment bolts.

Bearings and guides

They are made of long-life compound material to provide stability and minimum friction.

O-rings

Silicone and Viton O-rings are suitable for high and low-temperature applications.

| Item | Quantity | Name | Standard Material | Antiseptic treatment | Option material |

| 1 | 4 | Indicator | Polypropylene+GF | ———- | ———- |

| 2 | 1 | Indicator Plate | Polypropylene+GF | ———- | ———- |

| 3 | 1 | Jump Ring | Stainless Steel | Nickel | ———- |

| 4 | 1 | Bearing | Stainless Steel | ———- | ———- |

| 5 | 1 | Bearing | Polyphthalamide | ———- | ———- |

| 6 | 1 | Body | Extruded Aluminium Alloy | Hard anodizing | ———- |

| 7 | 2 | Bearing | Polyphthalamide | ———- | ———- |

| 8 | 2 | Piston | Die Cast Aluminium | Hard anodizing | ———- |

| 9 | 2 | O-ring | Nitrile(NBR70) | ———- | Viton/Silicone rubber |

| 10 | 2 | Bearing | Polyphthalamide | ———- | ———- |

| 11 | 8 | Bolt and Backstraps | Stainless Steel | ———- | ———- |

| 12 | 2 | Bolts | Stainless Steel | ———- | ———- |

| 13 | 2 | End-cap | Die Cast Aluminium | Chromium+polyester coating | ———- |

| 14 | 2 | O-ring | Nitrile(NBR70) | ———- | Viton/Silicone rubber |

| 15 | 2 | Guide | Polypropylene+GF | ———- | ———- |

| 16 | 1 | O-ring | Nitrile(NBR70) | ———- | Viton/Silicone rubber |

| 17 | 1 | Bearing | Nylon46 | ———- | ———- |

| 18 | 1 | Bearing | Polyphthalamide | ———- | ———- |

| 19 | 1 | Cam | Stainless Steel | ———- | ———- |

| 20 | 1 | Dirve shaft | Steel alloy | Nickel | ———- |

| 21 | 1 | Bearing | Nylon46 | ———- | ———- |

| 22 | 1 | O-ring | Nitrile(NBR70) | ———- | Viton/Silicone rubber |

| 23 | 1 | O-ring | Nitrile(NBR70) | ———- | Viton/Silicone rubber |

| 24 | 2 | Bolt&washer | Stainless Steel | ———- | ———- |

| 25 | 2 | Nut | Stainless Steel | ———- | ———- |

| 26 | 2 | Bolt | Stainless Steel | ———- | ———- |

| 27 | min.5/max.12 | Spring | High alloy Spring Steel | Epoxy resin coating | ———- |

| 28 | 1 | Spring Plate | Polypropylene+GF | ———- | ———- |

21. How to calibrate a pneumatic actuator?

Calibration of the pneumatic actuator is essential to know about any potential damage to the body. You can perform the calibration to the manufacturer’s manual and make the required adjustment. For calibration, you need to adjust the pneumatic signal. You need to read the pneumatic signal valve and compare it with the actuator’s range. If the difference is more than 3%, adjust the spring so that the indication works appropriately.

Check air failure and power failure by disconnecting air and power supply. Check the speed of stroking time. Note this results and compare them with the datasheet. For piston-type pneumatic actuator, check for any leakage, stroke range, and size.

22. What are the applications of rotary and linear pneumatic actuator?

Both rotary and linear pneumatic actuators are reliable and economical methods. Pneumatic actuators are popular because of their ruggedness, simplicity, and accessible structure. They are more compatible with the control systems. Rotary actuators are suitable in motion-control systems, clamps, and handlers.

Linear pneumatic actuators provide accurate and precise control overproduction. The minimum maintenance is required over its product life. Both rotary and linear pneumatic actuators are easy to install and provides improved automation in the workplace. The pneumatic actuator enhances efficiency and productivity.

Conclusion

Pneumatic actuators are the commonly used device in various industrial applications. It uses pneumatic pressure for opening, closing, and regulating valves. The features of double-piston gear, rack structure, aluminum cylinder, and constant output torque make it a highly efficient and flexible tool.

Instruthinkprovides a range of standard and customized pneumatic actuators to cope with the specific requirements of our customers. Our products are widely adopted using international standards. We make sure to inspect our products and then deliver quality products thoroughly.