- Indicators are easy to read from a distance.

- Customizable for different applications.

- Low cost.

- Easy to install.

- Simple to operate.

With a solid technical background, Instruthinkhas grown into a professional manufacturing giant. With headquarters covering an area of 21,600 square meters.

Instruthinkfloat level gauges are widely used in Oil and Gas industry, pipeline, petrochemical, metallurgical, power plants, food, pharmaceutical, and other industrial fields.

Our float level gauge contains the tape float level gauge, magnetic float level gauge, ball float level gauge, etc.

Welcome to visit our factory.

Instruthinkis your Best Float Level Gauge Supplier in UK

Instruthinkyour One-Step Solution Supplier of Float Level Gauge from UK

Instruthinkfloat level gauge is the simplest form of solid or liquid level measurement.

Instruthinkfloat level gauge is a device that rides on the surface of the fluid or solid within the storage vessel.

Instruthinksupply a wide range of float level gauge. Instruthinkfloat level gauge is manufactured to the highest standard.

Instruthinknot only supplies flow control solution but also supply flow measurement solution.

Welcome to understand more about our products.

Other Related Level Gauge

Your Best Float Level Gauge Solution Supplier

Float Level Gauge

With almost 21 years of industrial experience, Instruthinkis the leading flowmeter, float level gauges, and various instruments. Instruthinkhas strong technical background and headquarters covering a total area of 21600 square meters. The oil and gas industries, power plants, petrochemical, and metallurgical use Instruthinkfloat level gauge.

Below are the answers to all the queries of float level gauge that you might be looking for:

1. What is a float level gauge?

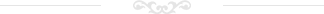

The float level gauge measures the height of the liquids present in the vessels, depending on their floating displacement. The connection of the float is with the measuring tape that rises and falls is dependent on the changes of the liquid present in the tank. Whenever the liquid level rises, the float also rises according to it, and the tape’s connection is with the spring drum that gets a twist. Whenever the liquid level starts to fall in the vessel, the float keeps dropping, and the tape pulls by the weight of the float. The movement of the float is transmitted towards the point-scale plate or counter by the gear mechanism.

2. Which products are in float level gauge?

- Tape float level gauge: is the float on the liquid surface displacing the liquid’s particular volume. The pointer weight balances this results in a loss in weight and the weight of the float. Its attachment is with the measuring wire and changes in the float’s liquid rise or falls by balancing the weight’s action. Therefore, following the level of the liquid. The tape float level gauge can only connect with the transmitter, with 4-20mA output or Hart, RS 485/Modbus.

- Magnetic float level gauge: The magnetic float level gauge is a kind of level sensor whose purpose is to measure the levels of the liquids. A floatable device in the magnetic float level gauge keeps floating in both low- and high-density fluids. You can also design this float level gauge according to the changes in the environment. In the magnetic float level gauge, there is a permanent magnet present in the float that keeps rising and falling, due to which the switch opens and closes. The float connects directly with the microswitch.

- Ball float level gauge: The ball float level gauge measures the level of the liquid directly. The design for the float is spherical and hollow as well. The attachment of the ball float is with the rod that keeps turning and connecting to the shaft. It shows the level of the liquid on the standard scale. The ball float level gauge’s working is straightforward as the ball keeps floating on the top of the liquid present in the tank. If there are any changes in the liquid level, the float changes the position towards the pointer whose connection is with the rotating shaft.

- Magnetostrictive level transmitter: The magnetostrictive level transmitter is the float level sensor that keeps providing the readings in real-time by creating competitive magnetic fields for the generation of the signals responding to the level of the liquid. You can find the characteristic of magnetostrictive in ferromagnetic materials. It can convert electromagnetic energy into mechanical energy or vibrations. The composition of the magnetostrictive level transmitter is by the three components: hollow steam, hollow float, and device electronics.

- Magnetic buoy float level gauge: This float level gauge helps measure the oil in tanks, thank farm, and different vessels present in the storage and transporting to the petroleum industry. The magnetic float level gauge flows the principle of equilibrium and changes the buoy’s position whenever there is a change in the liquid level. You can use magnetic buoy float level gauges in different mediums, including acidic, alkaline, corrosive, and high viscosity.

- Magnetic float level transmitter: The composition of the magnetic float level transmitter is by the float and sensing rod. The sensing rod has a resistance output proportional to the fluid level whenever the float rises or lowers the liquid level. The float level indicator is with the transmitter to deliver the 4-20mA output. The magnetic float level transmitter follows the principle of magnetism and buoyancy for generating the electrical output as the response of the rising and falling of the float available on the sensing rod.

3. What are the features of a float level gauge?

- The installation process of float level gauge is easy

- The float level gauge is simple to operate

- You can customize the float level gauge according to your applications

- Indicators are simple to read from the distance

- The float level gauge is applicable for all kinds of liquids and is suitable for measuring the content level.

- The oil and gas, petrochemical, pipeline, power plant, metallurgical, food, and pharmacy industries use float level gauge in industrial applications and processes.

- You can link the float level gauge with the transmitter

- The accuracy level of the float level gauge is 3mm

- The transmission options are available in float level gauge

- The float level gauge is also suitable for the majority of the latest designs of the storage tanks

4. What are the technical parameters for the tape float level gauge?

Following are the technical parameters for the tape float level gauge:

Mechanical part:

- Normal working condition: D2 grade ground

- The temperature of the surroundings in degrees Celsius: -40 to 85

- Relative humidity: 5%-100% that includes the moist and direct wet

- Atmospheric pressure: 86kPa-108kPa

- Measuring ranges: 0-6m, 0m-12m, 0m-18m, 0m-20m

- Measurement of tolerance: 4.5mm

- Sensitivity: 1.5mm

- Working pressure: 0MPa-4.0MPa

- Medium temperature: -40 degrees Celsius to 200 degrees Celsius

- Method for the display: a five-digit capacity decameter, meter, decimeter, centimeter, a millimeter is displayed by the counter of three digits and dial scale.

- Materials contacting the medium: ICR18NI9TI

Part of the transmitter for the output:

- Measuring range: 0m-22m

- Accuracy rate: 0.5%

- Error: 1mm

- Output: 4-20mA/4-20mA+Hart/RS485/Modbus

- Remote distance: <1000m

- Explosion proof: ExdIIBT4

- Degree: IP65

5. How is the level measurement in float level gauge?

The float level gauge uses the principle of the buoyant component that keeps floating on the surface of the liquid and changes the position whenever there is variation in the level of the liquid. There are many methods for indicating the class from the work of the float. You can see the conceptual working of the float level gauge in figure 8. The connection of the float is with the pulley of the chain, while the rotating part of the pulley has connectivity with the devices along with the measurement. The counterweight tightens the cable when the float moves upward, and the indicator keeps moving with the circular scale.

6. How does the float level gauge measure the level in the tanks and containers of ammonia and LPG?

The float level gauge is among those devices that measure the liquid present in the storage tanks, trucks, bottles, and domestic tanks. When the liquid level of the container starts changing, the floatable device of the float level gauge triggers the magnet to move the dial’s needle to show the fluid levels. To measure the stories in the tanks of ammonia and LPG, one must check the mounting position of the float level gauge, viscosity of the liquid, size, and part of the tank. These factors have an impact on the level measurement of the float level gauge. You can also use float level gauge in generators, compressors, construction, and agricultural machinery.

7. What are the advantages of using float level gauges?

- The lifespan of float level gauge is long, has stability, and is reliable

- You can install float level gauge easy and doesn’t require any maintenance

- The measuring medium does not affect the chemical and physical state. Such as electrical conductivity of the medium, temperature, pressure boiling, evaporation, and bubbling effects.

- You can also use the controller for controlling the upper and lower level of the liquid.

- In float level gauge, interface measurement along the two mediums of controlling densities is available.

- The design of the float level gauge is explosion-proof, so the float level gauge is appropriate for the explosive surroundings.

8. What is the working principle of float level gauge?

The design and production of float level gauges depend on the principle of buoyancy and static magnetic field. The float level gauge installation is on the top of the container with the help of a connection flange. The ball of the float keeps floating on the surface of the liquid. Whenever there is a change in the liquid level, the float ball starts moving up and down. The reed switch of the ball level gauge gets attracted magnetically for modifying the position of the liquid level into an electrical signal. You can see the actual position of the liquid in digital form through the digital instrument.

9. What is dial type float level gauge?

The dial-type float level gauge has floated, measuring wire, and indicating unit. The connection of the measuring wire is with the float on the liquid level that is directly proceeding to the indicator body and wounding on the wire drum. The rotations of the wire drum are transmitted by the gear transmission towards the dial indicator. Here, the pointer turns on the dial scale to show the level. The connection of the wire drum is with the constant drum, whose purpose is to extend the length of the wire depending on the variation of the level. That’s why the tension of the wire is always constant. The dial-type float level gauge is usually helpful in sewage and water tanks.

10. What is the purpose of using a reverse float level gauge?

The reverse float level gauge is unique with the simple system that doesn’t need any chemical outside the tank to provide the readings to the user. You can use a reverse float level gauge in every tank, including double wall SAFE tanks.

Reverse float level gauge offers some of the benefits that are as follows:

- There is no need to penetrate from the sidewalls of the tanks or exposing to chemicals

- All the parts are dry fit so that you can replace them easily

- There are no stains present on the clean pipe from the substances or UV attack

- There is no possibility of draining out the chemicals even there is a breakage in the tank due to the chemical present in the pipe.

- The rope is resistant to the chemical, so it helps in assembling the polypropylene.

- The rollers in the elbows are of high-quality PVC

- The addition of reverse calibration tape is for the capacity of the tank

- Supports for the free-standing pipes are also present

11. What are the instructions to install and maintain float level gauges?

Installation instructions of float level gauge:

- Before using the float level gauge, make sure that the liquid is in the verification time, and if not, then verify and replace in case of failure.

- Install the sensor in the horizontal direction, and the run-in length must fulfill the technicalities.

- Must tighten the connection between the explosion-proof junction box and sensor, so there is no rainwater leakage.

- Always follow the instruction manual for connecting the wirings to avoid the short circuit or wrong connection.

- The float level gauge must work continuously in the set measurement range and not exceed the capacity.

Maintenance instructions of float level gauge:

- After working on float level gauge for six months-1 years, the visual inspection of float level gauge and routine verification is essential.

- You must check the float level gauge to see whether it gets bend or deformation from the external force regularly to prevent the ball from falling.

- The verification time of the float level gauge is one year

- Examine the protective sleeve of the float level gauge for any leakage of the water

12. Who are the manufacturers of float level gauges?

The three leading manufacturers of float level gauges are UK, Canada, and the USA. In UK, Instruthinkis famous for manufacturing float level gauge that helps detect the level of the liquid present in the tight container of the industrial processes. Instruthinkis also the supplier of a massive range of float level gauges, including tape float level gauges, magnetic float level gauges, and ball float level gauges. Instruthinkalways follow high standards while manufacturing and supplying float level gauge in UK and other countries. At Instruthink, magnetostrictive level transmitter and magnetic level transmitter are also available with the float level gauge.

13. What is the role of specific gravity in float level gauge?

During the selection of float level gauges, it is essential to know the specific gravity of the measuring liquid. The specific gravity is the property whose relation is to the ratio of the object’s density to that of the water; after selecting the float level gauge that has particular specific gravity won’t sink. Remember, you must also note down the temperature changes of the liquid as it can also change the specific gravity. Its consideration is essential because the working of the float level gauge depends on its capability to measure the liquid accurately. Therefore, the accuracy is significant for the proper working of the float level gauge.

The formula of specific gravity: Specific gravity= density of the object/ density of the water

14. What is a carburetor carb float level gauge motorcycle tool for any motorbike?

The carburetor carb float level gauge motorcycle tool is suitable for measuring the height of the float level between the float and carburetor gasket surface. The size of the float is 16-78mm and adjustable to 0-40mm. The material is steel.

15. What is the float and tap level gauge?

The float and tap level gauge is a convenient mechanical gauge whose accuracy rate is high in mm. It is suitable for approximately 50 bar pressure and 400 degrees Celsius. The float and tap level gauge is right mainly for the oil depots, refineries, chemicals, and fertilizer industries, and you can use it for medium and large-size tanks along with empty tanks as well. The service kits are also available for severe, moderate, and extreme conditions according to the applications. In addition, there are options for the materials appropriate for the particular parts that involve the extreme temperature and pressure in the kits.

You can measure the level of the following liquids using the float and tap level gauge:

- Crudes

- Gasoline

- Water

- Solvents

- Diesel

- Chemical

- Addictive

- Solvents

- Jet fuel

16. How does the float type level switch work?

Generally, the float type level switch is the liquid level switch for the detection of the liquids. You can use this level switch on different locations the detect the level of the liquid. The float type level switch starts when the float keeps moving up and down due to the buoyancy. The reed switch present in the stem works by the magnet in the float, and output detects the signals. Moreover, sometimes the level meter cannot measure the level of the liquid with some of the viscosities and specific gravities. There is some situation when there is no possibility for the measurement. For example, you can measure the levels of high viscous liquids. The float stops working when the pressure in the tank is high or the specific gravity of the liquid is low. There are some solutions available to resolve these issues. The first solution is surface processing. Electrolytic grinding and buffing are present for the surface processing, and other solutions specify the high temperature. You can use the float type level switch approximately to 160 degrees Celsius, and the option of increasing the pressure is also available.

17. What is the measuring range of the float level gauge?

The measuring range of the float level gauge is comprehensive but has a limit. The benefit of using a float level gauge is that the material in the tank does not affect it. However, you can face some issues during the settings at the initial level. The float level gauge can also handle harsh conditions.

18. What is the difference between the displacer and float level gauge?

The float level gauge and displacer are helpful for the level measurement. The float level gauge floats on the top of the liquid. For interface detecting, the calibration of the displacer to the specific fluid gravity at the bottom starts flowing at the top of the lower fluid. The purpose of float level gauge and displacer is quite similar, but the displacer is completely water-log in the liquid. Therefore, you can use a displacer and float level gauge to measure the different fluids’ level interfaces. The float level gauge and displacer are among the most straightforward and economical technologies for the level measurement along with the sensor. However, some issues might occur during the usage of float level gauges and displacers. Like, they are only suitable for those liquids for which their calibration is done, and if there is any disorder in the tank, then installation of stilling wells is necessary.

Final thoughts:

The float level gauge is a device that keeps floating on the liquid or solid surface present in the storage container. Along with the flow controlling solution, Instruthinkis also supplying solutions for the flow measurement. You can use the team members of Instruthinkregarding the details of the float level gauge and other instruments. We always welcome our customers to deliver them the best high-quality products. So, place your order now through our official website, and even you can contact our representative on WhatsApp and Skype. Get your float level gauge within 7-10 working days.