- More than 20 years of manufacturing

- Registered as a world Brand in 20 countries.

- Hi-tech facilities

- Excellent team

- Competitive price

- ISO, ATEX, CE, Rohs, and SIL2 Certificates

InstruthinkYour Expert Supplier in Differential Pressure Level Transmitter in UK

With over 20 years of manufacturing experience, Instruthinkis your one-stop solution for differential pressure level transmitters. Instruthink’s 2 factories covering 30,000 m3 and 10 workshops, Instruthinkis your one-stop supplier for instrumentation solutions.

InstruthinkDifferential Pressure Level Transmitter can be externally installed or retrofitted to an existing vessel. It also can be isolated safely from the method using block valves for maintenance and testing.

With ISO, ATEX, CE, Rohs, and SIL2 certificates. Instruthinkhas 5 automation calibration systems with Germany’s imported cali8bration device.

You are welcome to visit our factory.

Your Expert for Differential Pressure Level Transmitter from UK

Why Use InstruthinkDifferential Pressure Level Transmitter for Your Project

InstruthinkDifferential Pressure Level Transmitter measures and monitors pressure levels in various industries. It is also an effective tool in measuring liquid levels.

InstruthinkDifferential Pressure Level Transmitter is suitable for measuring inlet and outlet pressure in the engine test setup, measuring pressure drop, fluid height, and measuring pressure in pharmaceutical industries.

Welcome to contact us for more information.

Hot Sales Differential Pressure Level Transmitter

Why Purchase Differential Pressure Level Transmitter from Instruthink

- Introduction

- Working Principle

- Calibration

- Certificates

- Application

Differential Pressure Level Transmitter – FAQ

A differential pressure transmitter is an instrument or device that measures the difference between two pressures. The low-side pressure reference point is compared with a high-side pressure. It can be either negative or positive, depending on which side has the higher value.

This guide will discuss the functions, advantages, principles of operation, specifications, and implementation of differential pressure level transmitters in various applications.

1. What is a differential pressure level transmitter?

Differential pressure level transmitter is an effective tool used in various industries to measure and monitor pressure levels. This instrument is also an effective technique to measure liquid levels.

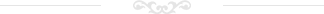

Initially, the differential pressure level transmitter has designed to measure the pressure level in pipes before and after the fluid encounter. These differential pressure level transmitters have two process connections to measure the drop in pressure between higher and lower points.

1. How does it measure pressure?

The pressure is measured when there is a drop in pressure between lower and higher points. It has a diaphragm that senses the force developed by the material in the vessel. The classical differential pressure transmitters can also measure the flow rates.

The differential pressure level transmitter measures the differential pressure between liquid and gaseous phases of the vessel. To get the precise calculations, you should include important factors such as the tank’s geometry, specific density, and pressure.

1. How differential pressure level transmitter works?

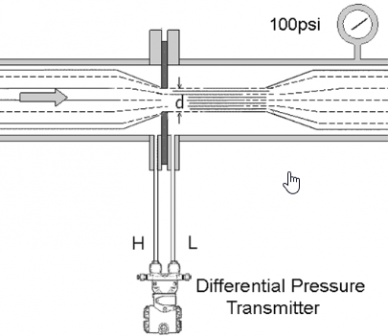

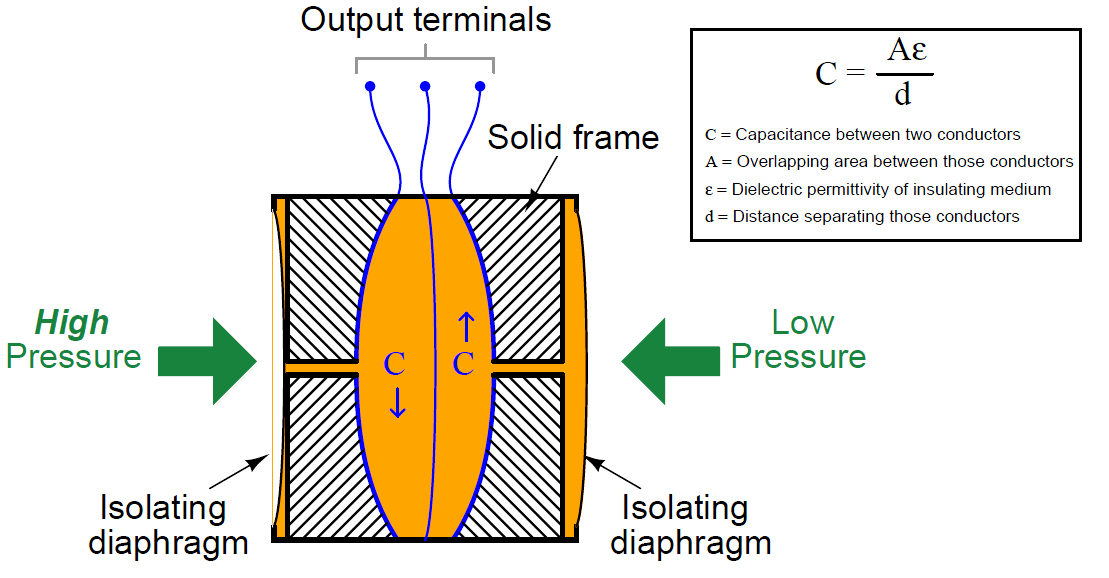

The differential pressure level transmitter works on the basic principle of differential capacitance. In it, the sensing element is the metal diaphragm that is located between two metal surfaces. The pressure sensors are accurate and rugged. The solid frames keep two isolating diaphragms from getting in contact with one another.

The higher-pressure isolating diaphragm gets pushed towards the metal frame, which causes the motion to be transferred to the sensing diaphragm. The excessive pressure on the diaphragm stops movement.

This limit of the diaphragm motion will stop exerting any force on the sensing diaphragm. The use of isolating the diaphragm will give the differential pressure level transmitter an excellent resistance.

The liquid fill is the main component that provides an over-resistance feature to the differential pressure level transmitter. For accurately turning the applied pressure into the capacitance, the diaphragm should not be in direct contact with the metal frame. For protecting the diaphragm against overpressure, it must be in contact to limit further travel.

1. What are the applications of differential pressure level transmitter?

The differential pressure level transmitter measures the liquid and gas flow as well as density and pressure. It is best for various applications, such as industrial data acquisition and control applications.

The differential pressure level transmitter is suitable for measuring inlet and outlet pressure in the engine test setup, measuring pressure drop, fluid height in tanks, and measuring pressure in pharmaceutical industries.

The differential pressure level transmitter is applicable for different measuring tasks. It is used as a level measurement in pressurized vessels. It is a very popular pressure measuring technique in the paper, chemical industry reactors, and pipelines through orifice plates.

2. What is the working principle of differential pressure level transmitter?

The differential pressure level transmitter consists of a sensing element with a metal diaphragm. The metal diaphragm is placed between two metal surfaces, and these metal surfaces are comprised of three plates.

The electrically insulating fluid is responsible for transferring motion from the isolating diaphragm to the sensing diaphragm if there is a difference of pressure across the cells, the diaphragm flex in the least pressure direction.

The sensing diaphragm has the spring element that means displacement is a function of applied force. The applied force is the function of differential pressure against the surface area of the diaphragm. The fluid pressure causes two forces that work against each other so that the force pressure area will be rewritten. The equation will be the reluctant force as a function of differential pressure and diaphragm area.

The applied force is related to diaphragm displacement while the diaphragm area is constant. The secondary function of the diaphragm is to act as a measuring displacement between two capacitors.

The capacitance is always inversely proportional to the distance, so the capacitance on the low-pressure side will increase more than the high-pressure side.

1. What is the construction of the differential pressure level transmitter?

The differential pressure level transmitter is suitable for various industrial applications for measuring pressure. It has a robust metal body housing the sensing element. The compartment housing surrounds the sensing element with electronic and mechanical components that translates the pressure into the instrumentation signal.

The pressure sensor in every differential pressure transmitter model design has the location at the bottom part of the instrument.

At the same time, the electronic is placed in the top half. The differential pressure level transmitter has two pressure ports for sensing different process fluid pressures. The pressure ports have ¼ inch female threads for real connection to the process.

These two ports have given the label of high and low. However, that labeling does not necessarily mean that the high port must always have a more significant pressure than the lower port. Instead, these labels reflect the effect of fluid pressure on the direction of the output.

2. How to measure and calculate differential pressure level transmitter?

The differential pressure level transmitter is versatile equipment that measures the pressure inside the system. It consists of a sensing cell and a transmitter. The diaphragm separates the cell where one chamber is high-pressure while the other is low-pressure.

For calculating the differential pressure level transmitter, the Pascal equation for hydrostatic pressure is used.

P=ρ *g*h

ρ= density of the liquid

g= acceleration due to gravity

h= height of the liquid

3. What are the main advantages of a differential pressure level transmitter?

The differential pressure level transmitter is the innovative solution to the traditional differential pressure transmitters. It offers many advantages with exceptional accuracy and stability. Following are some of the benefits of differential pressure level transmitter:

The level sensors used to measure pressure in differential pressure level transmitters can be mounted easily to the vessel’s surface.

It is applicable in various level measurement applications such as total level in vessels where other level measurements do not work effectively because of extensive changes in material formation.

The differential pressure level transmitter can measure fluid flow inside the pipe, which is less expensive and accurate. The orifice plate or flow nozzle reduces the diameter inside the pipe.

A differential pressure transmitter connects the high-pressure side to a larger diameter and the low-pressure side to a smaller diameter to measure the pressure before and after the flow rate. It is an accurate solution at a low cost.

4. What are the disadvantages of differential pressure level transmitters?

Although there are many advantages of differential pressure level transmitters, there are certain drawbacks as well.

When measuring the density of the process fluid, there are chances of errors in measurement because of temperature variations or changes in the process. Therefore, to get accurate results, you must maintain the density of the process at a constant level.

Differential pressure level transmitter works well for measuring clean liquids. However, it is essential to have two vessel penetrations for operation, which should be installed near the vessel base to prevent leakage.

You cannot use the differential transmitter for liquids such as paper pulp stock as it causes solidification.

The installation of the differential pressure level transmitter requires draining the vessel by stopping the process. Therefore, it could be a time-consuming procedure, especially when there are multiple vessels.

The capillary lines and impulse lines are vulnerable to outside factors. For instance, there is a risk of getting crushed in high-traffic areas.

5. What is auto-calibration of the differential pressure level transmitter?

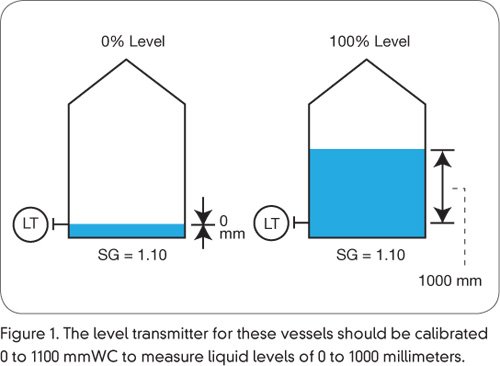

The differential pressure level transmitter can be calibrated to compensate for specific gravity. The calibration technique is used to calculate more complex installations at both 0% and 100%. The transmitter diaphragm generates the pressure is the liquid height times the specific gravity. Thus, when the vessel is at 0% level, the pressure is 0mm, and when the ship is at 100%, the pressure is 1000mm.

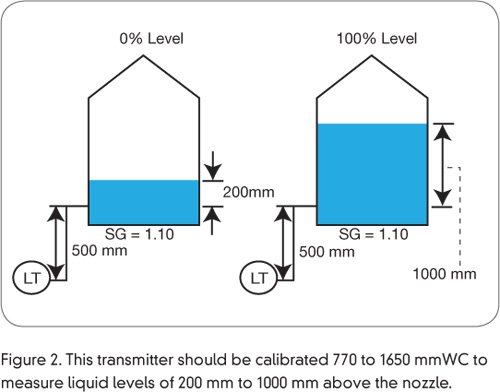

When calibrating the more complex applications, the measurement is taken from 200mm to 1000mm above the nozzle. In these cases, the differential pressure level transmitter is 500mm below the nozzle. The technique of measuring pressure at both 0% and 100% is the same.

At 100% level in these situations, the pressure at the transmitter is 1650 WC. Therefore the differential pressure level transmitter needs to be calibrated 770 to 1650 mmWC for measuring liquid levels of 200mm to 1000mm.

1. What are the spanning specifications of differential pressure level transmitters?

The measurement of differential pressure level transmitter should be according to certain specifications for ensuring accuracy. The span of the differential pressure level transmitter is measured by the difference between 100% and 0% calibration values. There is a minimum and maximum span of the differential pressure level transmitter. The calibration is done with spans between 400 mmWC and 4000 mmWC.

The transmitter at 0% level can be increased or decreased for up to 4000 mmWC. If the calibration does not meet the mentioned specifications, there are chances of significant error. The calibrations have a span greater than 400mmWC, and less than 4000mmWC.

2. What are the considerations while using differential pressure level transmitters?

Certain things need consideration when using the differential pressure level transmitter, such as changes in liquid, density, or changes in the composition of the liquid. Some factors can affect the measurement of the pressure. Changes in the specific gravity must remain constant so that the differential pressure techniques can be applied to various liquid level measurements.

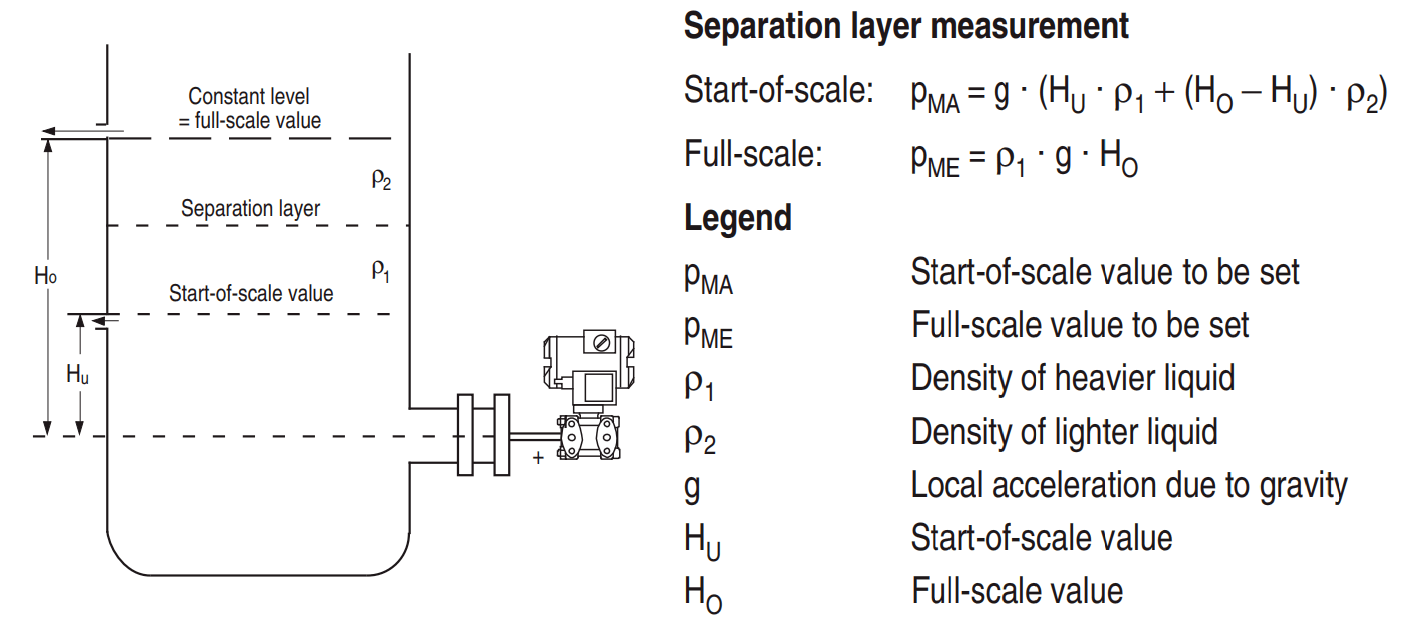

The differential pressure level transmitter measures liquid and gases in the pressurized vessels. The differential pressure measures the difference between static pressure and overall pressure. There are three variables to consider: pressure, density, and height. The sensor measures pressure, density is input, and height is the product level.

3. What is the calibration procedure of the differential pressure level transmitter?

To calibrate the differential pressure level transmitter at the field, you need a datasheet, pressure calibrator, multimeter, and HART communicator. Following steps need to be followed for calibrating the transmitter:

- Put the controller in the manual mode for the control loop by putting it on MOS for the ESD loop.

- Verify the parameters from the datasheet and hook up the HART communicator. The parameters include tag number, PV, LRV, and URV.

- Release pressure and measure low and high side liquid throughout the drain.

- Open the seal pot and seal liquid on the lower side by filling half of the seal pot.

- Hook up the pressure calibrator on the high side and isolate the valve.

- Use a multimeter to measure the current signal.

- When the transmitter is at zero levels, apply pressure. The multimeter will show 4mA. If it doesn’t, make zero adjustments using the HART communicator.

- Put loops back in the normal mode and fill the calibration form for future reference.

1. What are the types of differential pressure level transmitters?

JCLT differential pressure level transmitter

The JCLT differential pressure level transmitter is suitable for flow and pressure measurement applications. This pressure level transmitter has more accuracy and stability and has 4-2-mA output, including digital HART communication and automatic zero calibration.

The weatherproof and explosion-proof features make this product more reliable and long-term. It has a display of 5 digits programmable and 22 standard engineering units. The JCLT differential pressure level transmitter has a measuring range of

0-6.0 kPa and three internal keys for programming. With HART communicator, it has an accuracy of ±0.075%. It has a maximum operating temperature range of -40 to +250°C and a full pressure range of 40 MPa.

It has carbon steel or stainless steel 304 material of the adaptor/flange. The diaphragm has the material of stainless steel 316 L or Hastelloy B. The explosion-proof structure of the JCLT differential pressure level transmitter has a range of -25 to +85°C. Overall, this differential pressure level transmitter provides accurate and reliable measuring with two years of stability of 0.25%.

EJCLT differential pressure level transmitter

EJCLT differential pressure level transmitter is a reliable measuring tool for liquid, gas, or steam flow. It also measures density and pressure level inside the vessel. It has the output of 4-20Ma DC signal for measuring differential pressure.

The sensor system inside the EJCLT differential pressure level transmitter is reliable and measures accurate static pressure. The pressure measured is shown on the indicator monitored by the HART communicator. The other features of this differential pressure level transmitter include quick response, self-diagnostics, accurate measurement, and output for high and low-pressure alarms.

The EJCLT differential pressure level transmitter consists of a transmitter and installation level flange. It has the same operating principle as the differential pressure transmitter. The only difference is the high-pressure side of the transmission is different. When the pressure is loaded on the high side of the diaphragm, it passes from the isolating diaphragm and silicone oil to the sensor.

The amplifier damping constant of the EJCLT transmitter is 0.1 sec, while the damping constant of the sensor is 0.2-3 sec. The damping constant depends on the range compression ratio. This differential pressure level transmitter’s diaphragm and flange material are stainless steel, tantalum, Hastelloy C, and others and have a low measuring and accurate temperature measuring range.

2. What are the features of differential pressure level transmitters?

Following are the key features of the differential pressure level transmitter:

- The operator can calibrate the device using zero buttons, which means no calibrator is needed.

- The digital HART communicator is used for making the adjustments.

- If there is an abnormal operation while using the transmitter, there is a fail-safe mode process function.

- The differential pressure level transmitter has an accuracy range of up to ±0.075%.

- The ambient temperature of the transmitter improves the performance of the device.

- It has explosion-proof material and safety approval.

- The LCD is up to 270°C, and the mounting bracket can be rotated up t0 360°C.

3. What is the troubleshooting guide for operating the differential pressure level transmitter?

The differential pressure level transmitter has the design of operating in harsh and moderate environments. However, in extreme environments, they also fail to perform. In these cases, it is essential to identify and resolve the cause of malfunctioning. Therefore, it is always better to check the manufacturer’s manual while troubleshooting the differential pressure level transmitter.

There are different causes of the malfunctioning. However, we will discuss some common causes and how to recover from them.

Output

When your output is low, high, or there is no output, it means there is an error due to impulse piping, loop wiring, or sensing element. If there is an error with loop wiring, check the voltage of the transmitter, open circuits, and shorts, and verify the proper polarity at the terminal. For issues in impulse piping, check for leakages, liquid or gas entrapment in the piping, and debris in the transmitter. Finally, check for any sensing defects if there are issues with the sensing element.

Calibration

If you have not calibrated your differential pressure level transmitter properly, you need to thoroughly check the meter, sensors, and transmitter electronics. Check any leakage on the pressure source, and make sure it’s accurate. Make sure that the connectors and other electronics are clean and working properly.

4. What does differential pressure level transmitter measure?

The differential pressure level transmitter is used to measure the following components:

Density

When differential pressure level transmitter measures density, it measures the pressure difference between two points of the vertical plane. The difference in pressure gets the density value that is proportional to the pressure difference.

Flow

Differential pressure level transmitter measures flow in venturi tubes, orifice plates, and pitot tubes by measuring the relationship between differential pressure and flow rate. If you measure flow by your transmitter, it is essential to consider temperature, pressure, and fluid type.

Viscosity

When your differential pressure level transmitter is measuring viscosity, take the differential pressure on the orifice plates. This process works on the positive displacement principle at specific temperatures and pressure.

5. What are the installation conditions of the differential pressure level transmitter?

The differential pressure level transmitter can be flanged in any position, but it is preferable when the process flange axis is vertical. The electronic housing of the transmitter can be rotated at 360°. The transmitter has the minimum bend radius of capillary of 75mm. The ambient temperature has the maximum temperature of 85°C, and 20-65°C with LCD indicator.

The differential pressure level transmitter outputs a 4-20mA signal for measuring absolute/gauge pressure. It has digital communication with HART communicator. The damping constant is 0.1 sec, and the flange damping constant is 0.2-3 sec.

Conclusion

Differential pressure level transmitter is used widely in various industrial applications for measuring flow, density, and viscosity. It offers a flexible design that makes mounting easier. These transmitters provide accurate results and are capable of operating in harsh environments.

We offer varieties of differential pressure level transmitters which are ideal choices for your specific applications. We understand the need for quality differential pressure level transmitters, so we keep the safety and productivity of our products in mind. For more information, you can contact our team.

We will deliver you no matter where you are. Even, receive all information related to differential pressure level transmitter by calling on this number: 8651786989565 and you can mail us as well on: sales@instruthink.com