Hart pressure transmitters are the advantage and hot sales products in our factory, Instruthinkhas a strong technical background in UK for hart pressure transmitter production.

- High accuracy, best accuracy reaches 0.05%

- Fast delivery within 7 working days

- One-stop solution from digital sensor to hart pressure transmitter

- The special design of overload protection diaphragm design

- Overpressure protection sensor without pressure transmission loss

- Static pressure error reach ±0.05% / 10MPa

- Range ratio adjustment 100:1, wider adaptability

One Step Solution of Pressure Transmitter Manufacturer

Instruthinkhart pressure transmitter reaches ATEX explosion-proof standard, it can be applied in a dangerous area in various industry, including oil and gas, chemical, biogas industry, etc.

You can get differential accuracy hart pressure transmitter in Instruthinkfactory, such as capacitance hart pressure transmitter, its accuracy is 0.1%, silicon hart pressure transmitter, its accuracy is 0.075%. The best accuracy is 0.05%. There is a tracking calibration report for you. Each hart pressure transmitter is calibrated twice and tested 24 hours in the Instruthinkfactory.

We can supply you with one step hart pressure transmitter solution, our transmitter accuracy cover 0.1%, 0.075%, 0.065%,0.05%. Our heart pressure transmitter calibration system is imported from Germany.

If you cooperate with us, we can support you from the model selection to installation.

Welcome to contact us for hart pressure transmitter inquiry.

High-quality Hart Pressure Transmitter Manufacturer in UK.

Hart gauge pressure transmitters are widely applied in oil and gas, chemical, biogas, energy, food industry, etc.

Hart flush diaphragm pressure transmitter is especially for the media, which are viscous, paste-Like, adhesive, crystallizing, particulates containing, etc

Hart Differential pressure transmitter is an intelligent high precision transmitter, its normal accuracy is 0.075%, best accuracy reaches 0.05%.

Absolute hart pressure transmitter is measured the absolute pressure of the medium

Hart multivariable pressure transmitter has multi-parameter output application, such as pressure, temperature, static pressure, etc

Hart sanitary pressure transmitter is special designed for the food, beverage, pharmaceutical industry.

Your Best Hart Pressure Transmitter Supplier in UK

With a solid and strong technical background, Instruthink has close cooperation with several famous research institutes and groups in Europe.

With over 20 years of manufacturing experience on Hart pressure transmitters, Instruthinkdevelops the most complete product range for hart pressure transmitters in UK. There is three automatic hart pressure transmitter production line.

Hot Sales Hart Pressure Transmitter

Why Purchase Hart Pressure Transmitter from Instruthink

- Introduction

- Certificates

- Calibration

- Installation

- Application

There are three types hart pressure transmitters in Instruthink,

The first one is a capacitance type hart pressure transmitter, its accuracy is 0.1%. It is the popular hart pressure transmitter in the market.

The second one is silicon resistance hart pressure transmitter, it features high accuracy and stability, its normal accuracy is 0.075%, and best accuracy is 0.05%

The third one is piezoresistive hart pressure transmitter, it is a kind of economical hart pressure transmitter, its accuracy is 0.1%, 0,2%.

If you are the manufacturer of hart pressure transmitters, Instruthinkis the best working partner, you can get a complete package solution from Instruthink. From pressure sensor to pressure transmitter housing, Instruthinkwould give you the one-step solution.

Hart Pressure Transmitter- A Complete Guide

Instruthinkis the trained and skillful manufacturers of instruments like valves, flowmeters, transmitters, etc. It makes a Hart Pressure Transmitterthat that helps measure the gases, liquids, and air used in industrial applications. Instruthinkhas around 20 years of experience in manufacturing the Hart Pressure Transmitter and cooperates with the popular research institutes located in Europe. We continuously supply the Hart Pressure Transmitter over the accuracy covering the 0.1%, 0.075%, 0.065%,0.05%. Instruthinkimports the whole system of the Hart Pressure Transmitter from Germany.

Following are the answers to all your questions about the pressure transmitter:

Q1 – What is a Hart pressure transmitter?

![]()

The Hart Pressure Transmitter is a device whose purpose is to measure the pressure in gases, liquids, air, or oil. Hart Pressure transmitters are used in various industrial processes like filtration, feeding the chemical, pumping stations, wastewater industries, and others. You can even customize the pressure Transmitter through the pressure range, accuracy rate, type of connection, output, and other parameters. The Hart Pressure Transmitter also helps prevent accidents that might happen during the processes running in the industries. The applications of the Hart Pressure Transmitter depend on the type of pressure transmitter.

The HART Smart Pressure Transmitter is a high accuracy, high stability, LCD, intelligent pressure measuring instrument for real-time communication, complying with the HART protocol. The HART communicator allows the user to manage, adjust, or monitor process variables or configure the instrument on-site using the keypad, making it easy to operate.

It directly replaces the analog 2-wire 4-20mADC output transmitter, which works in a 2-wire mode.

The product adopts the latest application of digital technology in the field of sensor manufacturing, combined with the most advanced international pressure transmitter design and manufacturing technology, precision digital temperature compensation, and non-linear correction technology, safe and reliable explosion-proof structure design and standardized signal output, high accuracy, wide range coverage, suitable for places that require precision measurement of fluid pressure.

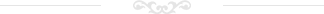

Q2-What is Hart’s communication protocol?

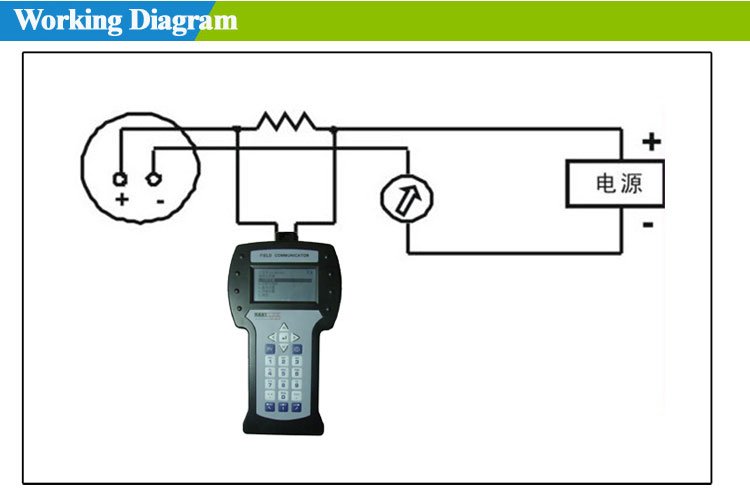

The HART (Highway Addressable Remote Transducer) protocol uses the Bell202-based FSK frequency shift keying signal to superimpose an audio digital signal with an amplitude of 0.5mA on a low-frequency 4-20mA analog signal for bi-directional digital communication at a data rate of 1200bps. The average value of the FSK signal is 0, which does not affect the size of the analog signal transmitted to the control system and ensures compatibility with existing analog systems. In HART protocol communication, the main variable and control information is transmitted by 4-20mA, where required, additional measurement, process parameters, device configuration, calibration, and diagnostic information is accessed via the HART protocol.

HART communication refers to the use of a half-duplex communication method, which is characterized by the implementation of digital signal communication on existing analog signal transmission lines, and belongs to the transitional products in the process of transformation from analog to digital systems, and thus has strong market competitiveness in the current transitional period and has been developed relatively quickly. HART communication superimposes an amplitude of 0.5mA on the low-frequency 4-20mA analog signal audio digital signal for two-way digital communication with a data rate of 1.2kbit/s.

The HART communication protocol specifies a series of commands that work on a command basis. It has three categories of commands; the first is called general commands, which all devices understand and perform; the second is called general behavioral commands, which provide functions that can be implemented in many field devices. This category includes a library of functions for the most commonly used field devices; the third is called special device commands, to facilitate work to implement special functions in certain devices. This category of commands is open for use in the Foundation and exclusive to the company that developed them. All three types of commands can usually be found together in a field device.

Q3-What is Hart’s communicator?

The HART Communicator combines the traditional functions of a multifunction calibrator with the HART communication function to perform routine calibrations including voltage, current, thermocouple, RTD, frequency, resistance, and pressure and can be used to communicate directly with all popular HART intelligent transmitters as a multifunction hand operator for the maintenance and diagnosis of HART instruments. Thus, it can be used for almost all field instrumentation maintenance and commissioning tasks, including troubleshooting, routine maintenance, start-up, calibration, etc.

Q4-How to calibrate pressure transmitter with hart communicator?

- Preparation.

We know that the pressure transmitter is connected to the pressure guide tube in the application. The usual practice requires the pressure guide tube and the pressure transmitter’s connector to be disassembled and then connected to the pressure source for calibration. This is very cumbersome and work, and labor-intensive. The biggest worry is to disassemble the joint when the pressure guide tube is wrenched off or a leakage problem. We know that no matter what type of pressure transmitter, its positive and negative pressure chamber has an exhaust, drain valve, or plug; this provides us with a convenient way to calibrate the pressure transmitter on-site. The transmitter has an exhaust; the drain valve is calibrated without removing the pressure guide tube.

To calibrate the pressure transmitter, first, close the positive and negative valves of the three-valve set, open the balancing valve, then unscrew the exhaust, drain valve, or cocks to empty it, then use a self-made connector to connect the positive pressure chamber instead of the exhaust, drain valve or cocks;. In contrast, the negative pressure chamber is kept unscrewed to make it open to the atmosphere. Next, the pressure source is connected to the homemade connector through a rubber hose, the balancing valve is closed, and the sealing of the air circuit is checked. Finally, the ammeter (voltmeter) and the HART communicator are connected to the output circuit of the transmitter, and the calibration is started after the power is preheated.

2.Conventional pressure transmitter calibration:

First, damping to zero states, adjust the zero point and then add the full degree of pressure to adjust the full range, so that the output is 20mA, in the field of calibration is fast, here to introduce the zero point, range of rapid adjustment method. When adjusting the zero point on the full range, almost no impact, but adjust the full range on the zero points has an impact, in the absence of migration, its impact is about 1/5 of the range adjustment amount, that is, the range up to adjust 1mA, the zero points will move up about 0.2mA, and vice versa.

For example: if you input a full range pressure of 100Kpa and the reading is 19.900mA, adapt the range potentiometer so that the output is 19.900 (20.000-19.900)*1.25=20.025mA. Suppose you increase the range by 0.125mA, the zero point increases by 1/5*0.125=0.025. Therefore, adapt the zero point potentiometer so that the output is 20.000mA. After the zero point and full range adjustment is normal, recheck the middle scales to see if they are out of tolerance? Make fine adjustments if necessary. Then carry out the adjustment work for migration, linearity, and damping.

III. Calibration of the intelligent pressure transmitter.

It is impossible to calibrate the Smart Transmitter using the conventional methods described above, as the HART hand operator structure principle dictates this. This is because the intelligent transmitter has a microprocessor chip working on the input data and the mechanical and circuitry between the input pressure source and the resulting 4-20mA current signal.

Therefore the tuning differs from the conventional method. In fact, the manufacturers of intelligent transmitters also have instructions for calibration, such as ABB’s transmitters, there are: “set range,” “re-quantitative range,” “fine-tuning” of the calibration. The “set range” operation is mainly configured through the digital setting of the LRV.URV, while the “re-range” operation requires the transmitter to be connected to a standard pressure source and is guided by a series of commands, with the transmitter sensing the actual The ‘rearranging operation requires the transmitter to be connected to a standard pressure source, guided by a series of commands, to sense the actual pressure and set the value directly. The initial and final set of the range is directly dependent on the real pressure input value. However, it is important to see that although the transmitter’s analog output is correctly related to the input value used, the digital readout of the process value will show a slightly different value, which can be calibrated using a fine adjustment term. As the individual components are both individually and necessarily jointly calibrated.

The actual calibration can therefore be carried out as follows:

I.First, make a 4-20mA fine adjustment to calibrate the transmitter’s internal D/A converter, which does not require an external pressure signal source as no sensing components are involved.

II.A full fine adjustment is then made to match the 4-20mA digital readout with the actually applied pressure signal, so a pressure signal source is required.

III.Finally, a rev-range is done so that the analog output 4-20mA is adjusted to match the external pressure signal source, which acts in the same way as the zero and range switches on the transmitter housing.

Q5-What are the tips for installing the pressure transmitter?

There are a few points for consideration while measuring from a pressure transmitter. First, all it needs is execution and planning.

- Location of connections of the process: locate the process connections on the top of the lining of the process, particularly for gases and sides of the lines for different fluids.

- Valves of isolation: there are pressure devices that require tapping points during the process. Consider the isolation valves between the processing fluid and equipment for the measurement if the device is out of order or calibration.

- Usage of impulse tubing: Keep the impulse tubing short as much as possible. The instruments in the gas applications should be self-draining. The achievement of self-draining is through the lines sloping that are proceeding the process to prevent the blocking of the fluids.

- Test and drain valves: During the process’s connectivity, the evaluation of testing and drain valves is essential. If the measuring fluid is corrosive, must provide the blowdown valve line.

- Construction of the sensor: selecting the suitable sensor is essential according to the application as there is also an involvement of physical conditions. The sensor might need isolation electronically and thermally by the medium of the process and external surroundings. You can achieve thermal and mechanical isolation through the movement of the sensor away from the flanging process towards the position place in the neck of housing electronics. This type of design releases mechanical stress on the cell. It results in the improvement in the performance of static pressure and removing of the sensor from direct heat.

- Effects of temperature: variations in large temperature affect the pressure transmitter. The most commonly used form for compensating temperature is the Wheatstone bridge. Along with the primary sensor, the placement of the dummy sensor is used to handle the effects of temperature changes. In this bridge arrangement, the dummy sensor omits the basic voltage of the sensor and, therefore, eliminates changes in the temperature during the measurement.

- Additional hardware: if there is a need for pulsation dampeners, then the flowing fluid and materials must be compatible with the measuring fluid in the process. Additionally, siphons must be suitable for all the vapors of temperature above 60 degrees Celsius where the condensation happens. Finally, if there is a need for diaphragm sealing, assess the requirement of the flushing connection.

- Effect of control loop: the sensing devices existing in the control loop have some impact whenever there is a change in the range of operations or response time. In pressure transmitter, the problem occurs for two main reasons: firstly, building up of the material on the sensing element giving longer response and secondly, over ranging might result in incorrect readings.

Q6-What is the procedure to calibrate the pressure transmitter?

- Isolate the main process isolation valve

- Depressurizing the Hart Pressure Transmitterthrough opening the vent valve

- Isolating the manifold valve and opening the vent plug

- Fixing and fitting of the proper instrument

- Connect the calibrator that fits into the plug of the vent where it is the entrance of the manifold valve.

- Make sure that the vent valve is open.

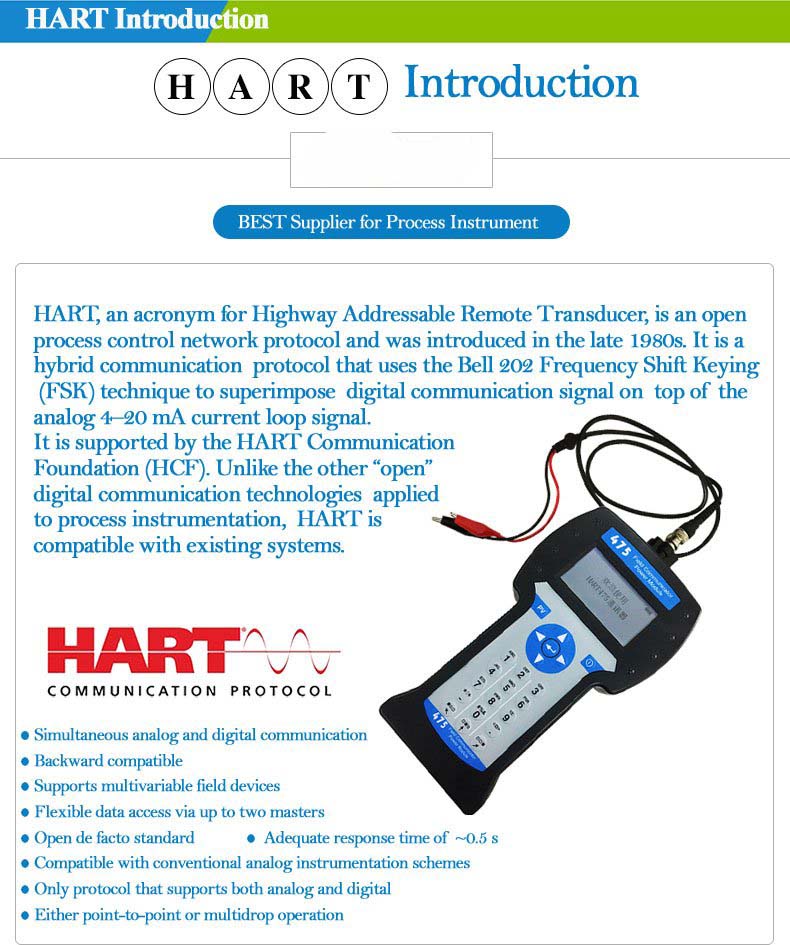

- The placement of the HART communicator cable must be according to the wiring diagram of the pressure transmitter.

- Apply the pressure according to the range offered by the Hart Pressure Transmitter or check the HART communicator.

- Keep monitoring the readings of the Hart Pressure Transmitterwhen you are applying the pressure for 25%, 50%, 75%, and distance from the range.

- If the Hart Pressure Transmitterrequires calibration, use the HART communicator for the calibrating purpose.

- The usage of HART communicator helps is zero and span trimming.

- After the calibration procedure, remove the pressure calibrator from the Hart Pressure Transmitter and flush the line.

- Must check that there is no hydraulic oil or water present inside the pressure transmitter.

- Close the vent plug

- Isolating the vent value and opening of the main isolation valve

- Slowly open the manifold isolation valve. If it opens fast, then sudden pressure can damage the diaphragm of the pressure transmitter.

- When the calibration process of the Hart Pressure Transmittercompletes, check that the Hart Pressure Transmitteris showing the readings properly.

- Enter the readings in the format of the calibration report

- Also, check the reading in DCS.

- Closing of the work permit from the operator of the field and shifting engineer.

Q7-What is the troubleshooting issues and solutions in pressure transmitter?

The reading of Hart Pressure TransmittermA is zero:

- Verification of power applying to the terminals of the signals

- Checking the wiring of the power for the reverse polarity

- Verify the terminal voltage that is 10.5V to 42.4V dc

- Check the opening diode across the testing terminal

No communication of Hart Pressure Transmitter with the field communicator:

- Authentication of the output between the range of 4mA to 20mA or the saturation levels

- Clean out the DC power supply towards the Hart Pressure Transmitter(maximum AC noise 0.2V from peak to peak)

- Checking of the loop resistance and the minimum is 25 ohms. (Power supplying voltage, the voltage of Hart Pressure Transmitter or loop current)

- Have poll of field communicator for all the addresses

The mA reading of the Hart Pressure Transmitteris too high or low:

- Verifying the applying pressure

- Check the points of the range

- Make sure that the output is not in an alarm condition (There is an availability of alarm options in some pressure transmitters)

- There can be the need of trimming the output

The Hart Pressure Transmitter is not responding to the changes of the applying pressure:

- Check the testing equipment

- There can be a blockage in the impulse pipe or low filling in the wet leg

- Do check that the calibration of the Hart Pressure Transmitter is done correctly

- Verification of the pressure calculation for the applications

Irregularity by the reading of digital pressure variable:

- There can be some fault in the equipment of the application in the line of pressure

- The reaction of the Hart Pressure Transmitter is not responding according to the equipment turning on or off.

- The setting of damping is proper in the application.

Inappropriate readings of mA:

- Check the source of power supply towards the Hart Pressure Transmitteris supplying current and voltage

- Check if there are any electrical interferences

- Verify the Hart Pressure Transmitteris grounded properly

- Check the shield for twisting the pair for grounding at only one end

Q8-What are the applications of pressure transmitters?

- Differential pressure is the difference existing in the magnitude between the value of the pressure and reference pressure. You can consider the absolute pressure as the differential pressure in the full vacuum or zero absolute as the reference one. Gauge pressure is also available as an option for the consideration of differential pressure. And the atmospheric pressure is the reference pressure.

- Flow: the common application of a Hart Pressure Transmitteris sensing the rate of the flow. The main element has an internal restriction that causes the reduction in the cross-section area of the pipe from where the process is flowing. It helps in increasing the velocity of fluid that is passing from the restriction. The fluid from upstream from the restriction has a lower speed. Here, you can observe the difference in the static pressure producing as the outcome decreases the fluid’s potential energy.

- Level of the liquid: You can measure the level of the liquid by using the pressure transmitter. Its determination depends on the opening or closing of the tank to the atmosphere.

- Level of the tank: (open tank) the measurement of the liquid level of the open tank means the tank is open in the atmosphere. In these applications, the change in the atmosphere directly affects the pressure of the processing fluid in the tank. In this kind of level measurement application, the lower side of the Hart Pressure Transmittermeasures the atmospheric pressure. It omits all the effects of the atmospheric pressure present on the level of the fluid tank. The connection of the higher side of the Hart Pressure Transmitteris with the tank and measuring the actual level of the fluid present in the tank.

- Close tank: it is the application where the tank gets seals from the atmosphere. As the process fills the fluid in the tank or empties it, the tank’s pressure proceeds to vacuum—the change in the pressure existing inside the tank affects the measuring level of the fluid. Piping the lower side of the Hart Pressure Transmitter to the top of the tank quickly does this task.

- Measurement of bubble tube level: one more method to measure the level is by the bubble tube. The constant air pressure is compatible with the tank’s contents, and maintenance is on the pipe inserting into the tank. As the level begins to change, the measuring pressure from the back of the Hart Pressure Transmitter is the direct level measurement. The advantage is that the pipe material is only exposing to the process, not the pressure transmitter. Although, the process is not sensitive to the bubbling of the gas through it.

- Measurement of interface level: actually, it measures the level of the liquid of the interface between the two different liquids like oil and water. Both liquids have different densities, and the distance remains constant when the top level in the tank is above the top of the tap. There is a change in the density, so the hydraulic pressure will also change the interface of the modifying level. You can apply this measure in both open and closed tanks.

- Measurement of the density: using the above principle, you can also measure density in the tank. The similar liquids with different densities in the tank keep exerting the pressure on the Hart Pressure Transmitterdepending on the changes in the density. When the level is above the tap of the top, the Hart Pressure Transmitterresponds to the changes in density when the distance remains constant. With the increase of density, the pressure on the lower side of the tap also increases along with the output of the pressure transmitter.

- The volume of the fluid in the tank: After determining the fluid level in the tank, you can also calculate the volume of the processing fluid. It is possible only when the relationship between the volume and measuring level is linear for the tanks of cylindrical shapes. This relation does not apply to other shapes.

Q9-What are the features of a Hart pressure transmitter?

- Receiving the alerts regarding the process: The diagnostics at the advanced level create the alerts regarding the process. It permits the owners of the process to make important adjustments at the right timings. It is helpful in monitoring and detecting the issues affecting the power supply, wiring, and grounding. You can also set alerts regarding the temperature for understanding if the temperature starts to the dropdown. It provides you with insights for maintenance and safety purposes.

- Local operator interface: There are built-in buttons available for configuration that permit quick commissioning.

- Wireless technology: This technology helps add new pressure points easily in different plant areas, and it was not possible before. The information delivered by the Hart Pressure Transmitterhelps optimize the efficiencies of the process and reduce human interaction in high-risk areas.

Q11 – How to configure pressure transmitter?

Mostly, the configuration of the Hart Pressure Transmitteris according to the guidelines of the manufacturer. Below are the basic steps to configure the Hart Pressure Transmitterthat leads towards the precise commissioning of the pressure transmitter.

- Connection of the Hart Pressure Transmitteris on the bench by using the HART communicator

- Set the process of the application loop to the manual. The HART communicator helps in promoting this activity. Next, connect the equipment of the bench and loops of the wiring according to the wiring diagrams.

- Check the default data for configuration by using the HART communicator

- Reviewing the output parameters in digital form before the performance of online operations present in the pressure transmitter. It informs you that the Hart Pressure Transmitter is working accurately and configuring the variables of the correct process.

- The process variable units, output (transferring function), and values are in the range.

Q12 – Which industries use pressure transmitters?

The Hart Pressure Transmitteris famous for offering reliability in a risky environment, which deals with great shocks, vibration levels, and corrosive medium. The Hart Pressure Transmitter also gives accurate results regarding the measurement where there is diversity in the applications. Like molding of the injection, equipment for the production of steel and medical equipment, etc. below are the industries that are using pressure transmitters:

- Aerospace

- Automotive

- Utilities

- Oil and gas

- Pulp and paper

- Food and beverages

- Marine and heavy equipment

- Vehicles

Q13 – What is the difference between the Hart Pressure Transmitter and pressure gauge?

- The accuracy rate of the Hart Pressure Transmitteris higher than the pressure gauge. That’s why the standard instruments need calibration of pressure transmitters.

- The pressure gauge only needs the verification between the pair of input and output. At the same time, the Hart Pressure Transmitterrequires the verification between the input and communicating data.

- The calibration of the pressure gauge is according to the corresponding measurement—the Hart Pressure Transmitterrequires new construction from the manufacturer.

- The output of the pressure gauge is the indication on the scale that is easy to read. The Hart Pressure Transmitteris analog output and needs to connect with an ammeter responding to the display accuracy level.

- The accuracy of the pressure gauge is low, and you cannot operate it manually. You need to check the difference between pressurizing and depressurizing. The Hart Pressure Transmitteronly requires calibration at the zero point and full scaling mostly.

Final Thoughts:

Instruthinkis technically strong in manufacturing and supplying Hart Pressure Transmitter from UK to other parts of the world. We are also meeting the standards of ATEX explosion-proof so that you can apply Hart Pressure Transmitter to the risky areas of your industries. We also submit calibration reports to your customers. Instruthinkteam welcomes you for contacting me regarding all the queries and details regarding the pressure transmitter. There is a complete range of Hart Pressure Transmitteravailable at Instruthinkcorresponding to your application. Our cooperation is helpful for you as we support our valued customers from selecting the model to the installation process. So, please don’t wait and contact Instruthinknow on our official number or even mail us. Our support team is also available on Skype and WhatsApp for convenience. Order the most famous Hart Pressure Transmitter from Instruthinknow and get it to deliver within 7 working days.