The Paper Mill industry is one of the primary industries in UK, with the increasing update of the technology in domestic paper enterprises. Particular paper enterprises have gradually started replacing the traditional differential pressure flowmeter with an electromagnetic flowmeter. At the same time, the flow meter manufacturer also put forward higher requirements to promote the technical progress of the electromagnetic flowmeter.

1. Electromagnetic Flowmeter working principle and performance

Electromagnetic flowmeter by the sensor, converter, display, and other components, is based on Faraday’s Law of electromagnetic induction made of measurement of conductive fluid flow instrument. The electromagnetic flowmeter has unique advantages that cannot be compared with other flowmeters, especially for dirty fluid and corrosion fluid measurement.

In the late 70s to 80s, a breakthrough in technology made the Electromagnetic flowmeter a modern industrial field instrument and flow monitoring instrument.

1.1 The main advantages of Electromagnetic Flowmeter

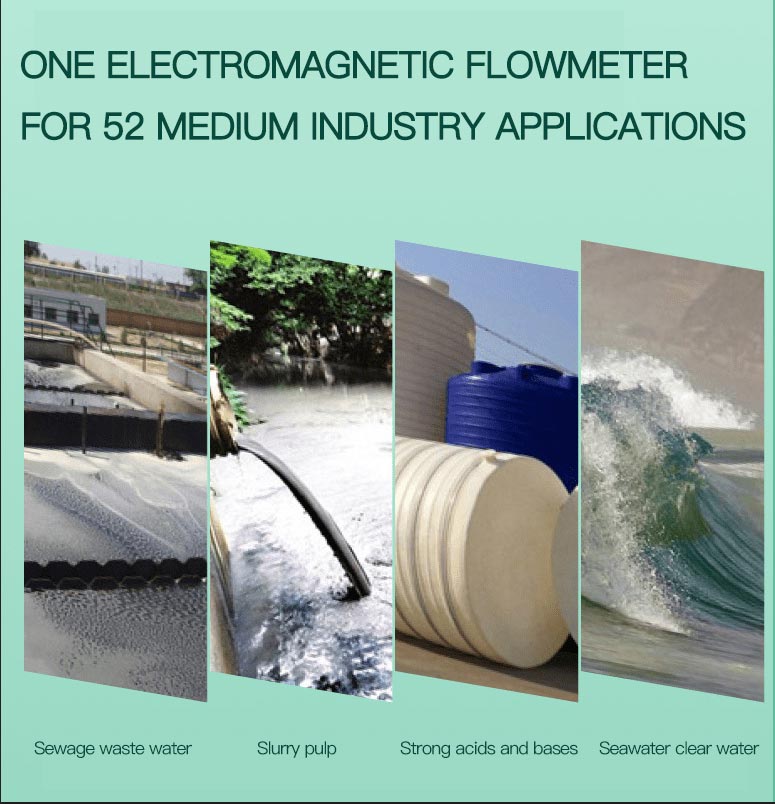

1.1.1 Because the measurement channel is a section of smooth straight tube, it will not block, so it is especially suitable for solid particles of liquid-solid two-phase fluid, such as pulp, sewage, mud, etc., no pressure loss, good energy-saving effect.

- Stable and reliable performance,

- high metering accuracy,

- long service life.

- It is not affected by changes in humidity, density, viscosity, and pressure of the fluid.

- Extensive flow range

- a wide range of caliber.

1.1.2 Suitable for the measurement of corrosive fluids.

1.2 The disadvantages of Electromagnetic Flowmeters

1.2.1 Not suitable for measuring petroleum product fluids.

1.2.2 Not suitable for gases, steam, and liquids containing large air bubbles.

1.2.3 Not suitable for high-temperature applications.

1.2.4 There are specific requirements for site installation.

- The application analysis of Electromagnetic Flowmeter for Paper Industry

Papermaking is a continuous production process, so the constant and orderly control of the production line becomes a bottleneck that limits the quality and yield of the finished paper. To effectively stabilize the quality of the finished article, electromagnetic flow meters play an essential role in this regard.

2.1 Application of electromagnetic flowmeters for slurry supply systems

The pulp supply system consists of the following stages:

1)the pulping process.

2) the pulping process.

3) the pulp preparation process.

In the process of pulping, the use of an electromagnetic flowmeter allows for accurate measurement of the pulping flow to ensure the stability of the pulping material and the stability of the subsequent pulping process. In the pulping process, the electromagnetic flowmeter and the regulating valve form a PID adjustment circuit to ensure a stable flow of pulp into the pan mill, thus improving the efficiency of the pan mill, stabilizing the pulp’s snap, and thus improving the quality of the pulping.

In the pulping process, the following conditions must be met:

- The pulp ratio and consistency must be constant, with no more than ±2% (fluctuations according to paper requirements).

- The pulp delivered to the paper machine must be stable to ensure a regular supply to the paper machine.

- Reserve a certain amount of pulp, to adapt to changes in the speed and variety of the paper machine.

Therefore, the essential thing in the pulp distribution chain is the control of the pulp flow.

The electromagnetic flowmeter is installed at the outlet of the pulp pump, and the pulp flow rate is adjusted using a control valve, which can ensure each type of pulp is regulated according to the ratio required by the process so that it can achieve a stable and even balance of pulp in the end.

2.2 Application of Electromagnetic Flowmeters for Paper Flow Feeding Systems

The entire papermaking system, pulping, pulp section is a vital link, but if the subsequent section is not ideal, it is still not qualified for the whole of the paper machine. Therefore, the flow feed system of papermaking takes on a more critical role, and its stability is directly related to the physical indicators such as the quantitative, moisture, and ash content of the finished paper. It is an essential part of the qualified paper.

Therefore, in this system, we detect and control the flow of pulp and filler and adjust the flow of pulp through the pulp dosing valve to stabilize the subsequent dosing of the finished paper. In addition, the filler flow rate is regulated by the filler regulating valve to stabilize the ash content of the next paper production. The electromagnetic flowmeter plays a significant role in this system, which plays an essential role in improving the quality of the finished paper.

2.3 Application of Electromagnetic Flowmeters in Chemical Preparation and Addition Systems

As a large number of chemicals are used in the deinking, pulping, flow feeding, coating, and sizing parts, in the preparation of chemicals, it is necessary to ensure the stable performance and concentration of each batch of chemicals; in use, the amount added to them has strict requirements to ensure the stable quality of the finished paper. Therefore, in the preparation of chemicals, we use corrosion-resistant electromagnetic flowmeters to measure each component of chemicals, with a control valve for flow adjustment and finally stabilize the performance of chemicals. In the chemical addition system, corrosion-resistant electromagnetic flow meters are used for the metering of the chemicals, with regulating valves for flow regulation, ensuring that the chemicals added to the paper machine system are quantitative and at the same time stable. This plays a vital role in the quality of the finished paper.

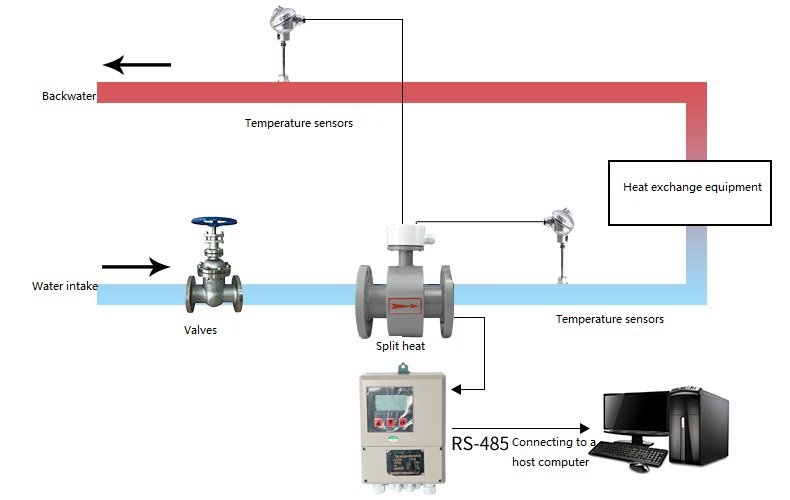

2.4 Application of Electromagnetic Flowmeters for Water Systems

The paper industry is a high energy consumption enterprise. Water, electricity, and steam consumption accounted for a large proportion of the national “Eleventh Five-Year” period on the paper industry energy consumption assessment, eliminating most of the high energy consumption, low capacity of small enterprises. Therefore, water-saving has also become the focus of transformation in the paper industry.

The electromagnetic flowmeter has a large range of measuring aperture, it can replace the electronic unit without interrupting the work, it need low power consumption by wetted part of stainless steel or ceramic structure, there is no moving parts, and it is maintenance-free, it has a lot of advantage that makes it the ideal flowmeter for measuring industrial water, paper white water and sewage in the paper industry. By monitoring and assessing the flow rate of the main inlet pipe, the main sewage pipe, and the white water circulating in the workshop of each paper workshop, effectively reduces the water consumption of tons of paper, reduces the waste of water resources in each link, and improves the utilization rate of circulating water in the workshop.

After many years of practice, an electromagnetic flowmeter in the field of paper is commonly used PTFE (for pulp, white water, industrial water) or other fluorine plastic lining (for chemicals), electrodes are selected according to the nature of different liquids, the actual results are satisfactory.

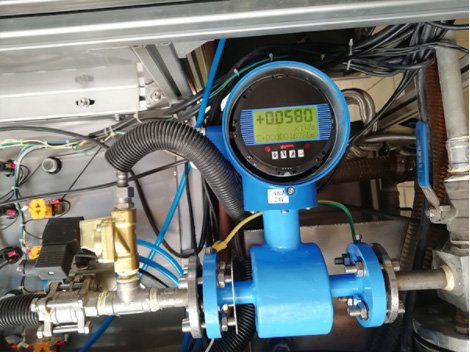

3. Some notes on the installation of Electromagnetic Flowmeters:

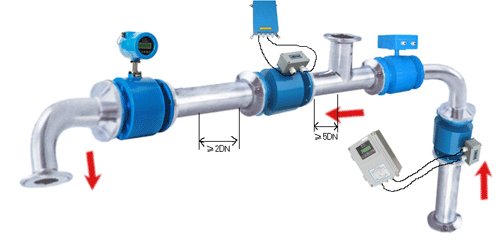

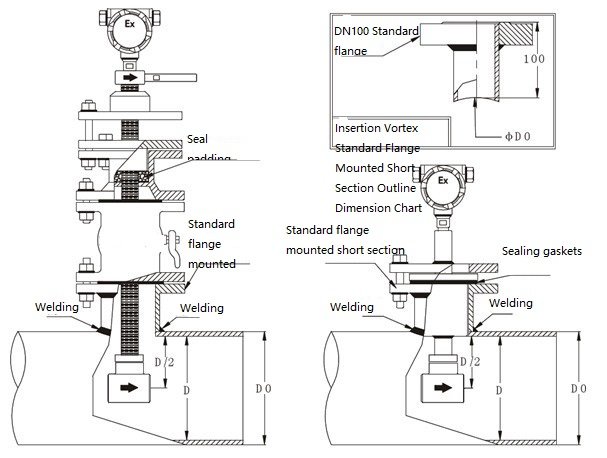

3.1 Either horizontal or vertical installation is possible

In the measurement of slurry, an electromagnetic flowmeter is best installed vertically, and the fluid flows from the bottom up. This ensures that the measuring tube is filled with the measured medium and avoids the disadvantages of localized wear and tear on the lower half of the electromagnetic flowmeter when installed horizontally and the precipitation of the solid phase at low flow rates.

3.2 Installation environment

- It should avoid direct sunlight and rainwater;

- Far away from large motors and transformers in the vicinity to avoid electromagnetic field interference;

- Avoid too much vibration of the pipeline ;

- If there is strong vibration in the pipeline system, supports can be added to the pipes on both sides of the sensor.

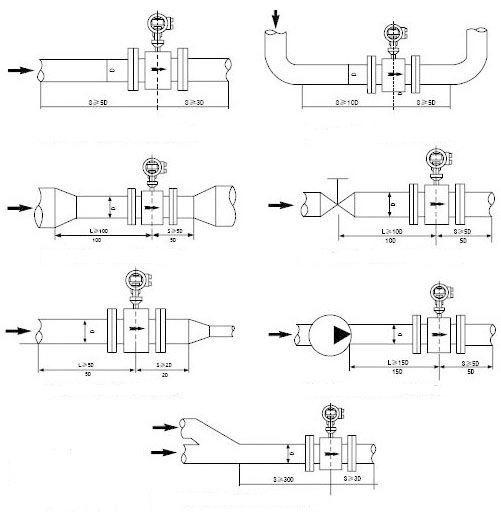

3.3 Straight pipe section requirements

The general electromagnetic flowmeter requires 5D on the upstream side and 3D on the downstream side to ensure the accuracy of the electromagnetic flowmeter. 10D on the upstream side and 3D on the downstream side are required for high accuracy meters. When the straight pipe section is not enough, the flow velocity in the tube is non-axisymmetric distribution, and the measurement will cause errors.

3.4 Grounding

The electromagnetic flowmeter requires separate earthing. If the pipe is coated with an insulating layer or a non-metallic conduit, grounding rings should be installed on both sides of the sensor. An electromagnetic flowmeter is vulnerable to external electromagnetic interference. Therefore, good grounding determines the accuracy of the measurement.

3.5 Avoid negative pressure in the pipe, especially with PTFE PTFE lining.

3.6 Installation of the transducer and connection cable.

The distance between the converter and the sensor of a split-type electromagnetic flowmeter is limited by the conductivity of the measured medium and the type of signal cable. The conductivity of the fluid to be measured is within a certain range and determines the maximum length of the cable between the sensor and the converter. The line uses the cable type supplied by the manufacturer with the instrument. Single-layer shielded cables are generally used for industrial water or acid and alkali fluids and can usually transmit up to 100 m. For media conductivity below 100 μs/cm, a two-core double-shielded drive shield cable is required. For lower conductivity and longer transmission distances, there are also provisions for 3-layer shielded cables.

4. Conclusion

The current foreign mass flowmeter is developing rapidly, but the electromagnetic flowmeter still occupies the dominant position in the paper industry liquid measurement. Its stable performance, easy maintenance, cost-effectiveness, and other characteristics determine its place in the paper industry.