Your cart is currently empty!

Professional Coriolis Mass Flowmeter Manufacturer

InstruthinkGive You Best Coriolis Mass Flowmeter Solution

InstruthinkCoriolis mass flowmeter provides the best mass flow, density, and temperature measurement performance, and also calculates volume flow, total flow, and fluid composition in real-time.

You can use InstruthinkCoriolis mass flowmeter for the most complex and challenging environment, include liquid, gas, and slurry applications, It is widely used in industries of chemicals, food & beverages, oil & gas, pharmaceuticals, power plant, pulp & paper, wastewater treatment.

With 20 years of experience, Instruthinkhas sound experience in Coriolis mass flowmeter manufacturing and application. If you cooperate with Instruthink, you don’t need to worry about the model selection and installation. There will be a professional team to guide you.

The signal transmitter of our flowmeter is employed with a digital signal processor, and dynamic vibration balance circuit to deliver fast response but accurate measurement performance. You can carry the configuration, diagnostics, and data recording easily by HART or Modbus RTU communication.

Welcome to send us an inquiry for Coriolis mass flowmeter

Full package of Coriolis Mass Flowmeter Solution

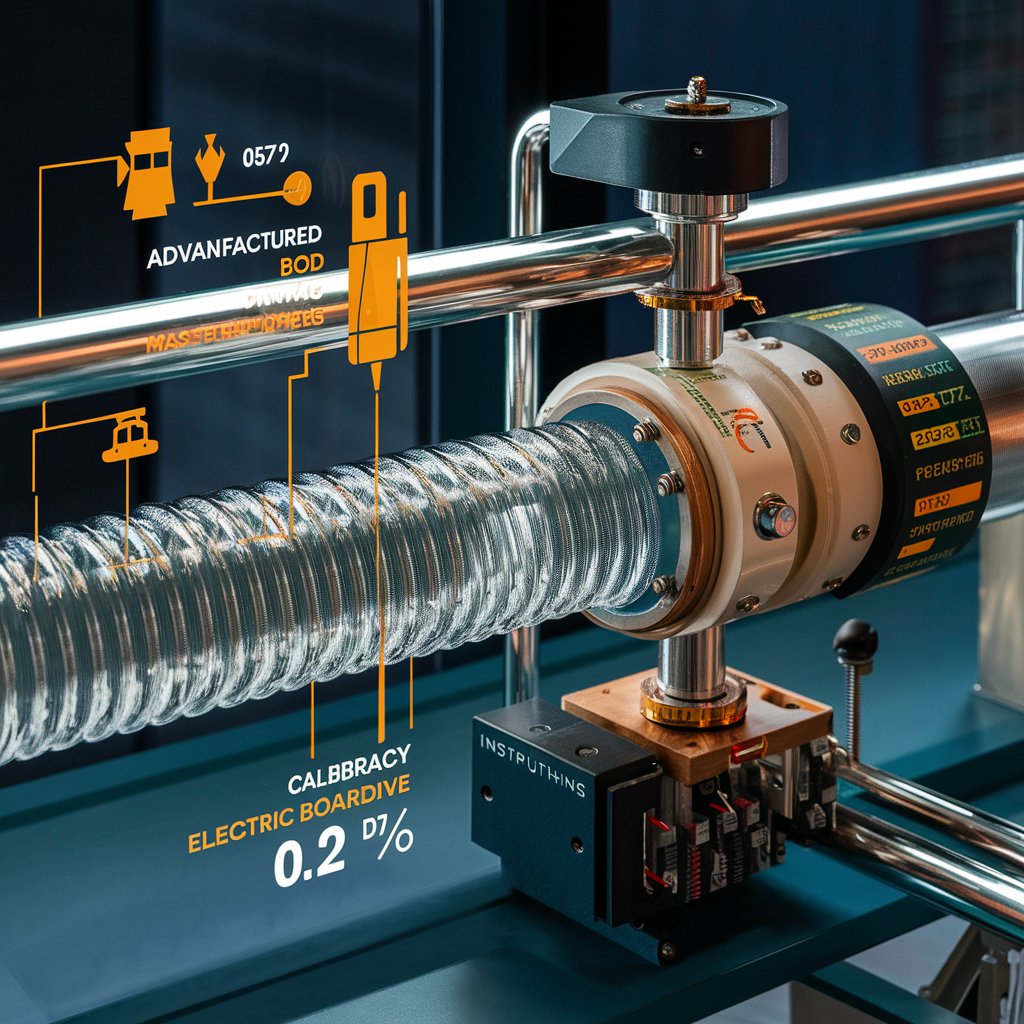

InstruthinkCoriolis mass flowmeter is designed according to the principle of Coriolis force, once there is flow passing through the tube, Coriolis force will give rise to deflection on the vibration of two pipes and the deflection of vibration is directly proportional to the mass flow of fluid.

With an advanced calibrated device, our Coriolis mass flowmeter accuracy can reach 0.2%. All the electric board and body part are made by ourself. So, our delivery time is very fast.

Why Purchase Coriolis Mass Flowmeter from Instruthink

- Introduction

- Technical Parameter

- Workshop

- Installation

- Application

What does the Coriolis mass flowmeter do?

Coriolis mass flowmeter has a different design than thermal or differential mass flow meters. It measures mass through inertia. Liquid or gas flows through the tube. Under the effect of vibration, the acceleration generates the twisting force on the tube. In most Coriolis mass flowmeters, dual-curved tubes are used for more sensitivity and lower pressure drop.

Coriolis mass flowmeter is considered the most accurate but vulnerable to errors when bubbles are present in the liquid. These bubbles can cause noise and create splashing within the tube.

How does the Coriolis mass flowmeter measures density?

You can use the Coriolis flowmeter to measure the density of the liquids as well. The flowmeter vibrates at resonant frequency alongside the sensing tube and the fluid density in the tube. The electrodynamics sensors allow drive frequency to convert into resonant frequency. As the fluid density changes, this causes the change in resonant frequency, so the resonant frequency is dependent on the liquid density.

You can use the RTD (Resistance Temperature Device) to overcome density due to the temperature change and vibrating devices to measure the density of liquids. However, this is not an exact way to measure the density of the fluids because of the sensitivity of these vibrating devices.

What are the typical applications of Coriolis mass flowmeter?

Coriolis mass flowmeters are gaining prominence in flowmeter applications. There has been a steady technical improvement in the structure since they came into the 1970s. As a result, their accuracy and acceptance have increased in the industries. In the process industries, Coriolis mass flowmeter represents a fast-growing percentage of flowmeter applications.

Applications of Coriolis mass flowmeter continue to expand in the petroleum industry. These applications include liquid separators, crude oil, liquid pipelines, refinery applications, viscosity measurements, Lease Automated Custody Transfer (LACT), etc. In addition, other applications unique to Coriolis mass flowmeter are combined with mass flow measurement and online density measurements.